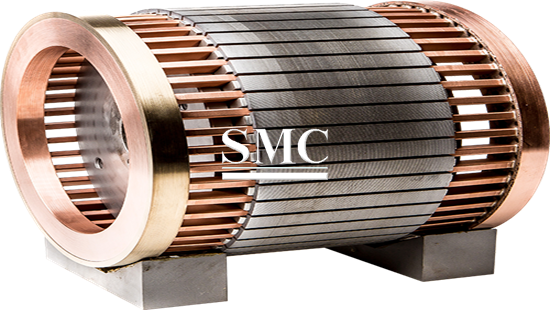

Copper rotor motors’ advantages:

1. Improve efficiency. Casting copper rotors instead of aluminum rotors can significantly improve the efficiency of small and medium-sized motors, and saves a lot of energy. Taking the Y132M-4 7.5KW motor as an example, after replacing the cast copper rotor, the motor efficiency increased from 87% to 90.4%. According to the calculation of the motor for ten years, the electricity cost can be saved by 16080 yuan, which is 16 times the replacement cost, and the benefit is very obvious. At present, a copper rotor induction motor with IE5 efficiency level has been developed, and the measured efficiency of 15HP-4P motor can reach 93.6%.

2. Reduce the temperature rise. Taking a 25HP 18.7KW motor as an example, the temperature rise of a copper rotor motor is 41% lower than that of an aluminum rotor motor, only 47.2 ℃. The operating temperature of the motor decreases by 10 degrees Celsius, the service life can be doubled. Therefore, the copper rotor motor can effectively extend the life of the motor. At the same time, it also increases electrical safety, and is especially suitable for explosive special environments.

3. Reduce volume, weight and cost. At the same efficiency, the volume of the cast copper rotor motor is reduced by about 15% compared with the aluminum rotor motor, which is suitable for the application of the base motor, such as: reducer motor, compressor motor and pump motor. By optimizing the design, the weight of the cast copper rotor motor can be reduced by about 20%. Such as: 15 HP TEFC motor converted to cast copper rotor weight reduction of 8KG. In terms of cost, the cast copper rotor motor with the same efficiency can be reduced by about 10%. When the price of copper decreases or the price difference between copper and aluminum becomes smaller, the cost reduction will become more obvious.

4. Corrosion resistance. The excellent corrosion resistance of copper makes the copper rotor very suitable for application scenarios such as brine pumps and hot water circulation pumps.

Guest contributors are welcome at the Alloy Wiki.It is a weekly wiki and guide on alloy information and processing technology, while also about the vast array of opportunities that are present in manufacturing. Our team of writers consists of a Machining Material Supplier / Machinist / Tool and Die Maker, a Biomedical Engineer / Product Development Engineer, a Job Development Coordinator / Adjunct Professor, and a President and CEO of a manufacturing facility.

Link to this article:Copper Rotor Motors

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^