resistance and corrosion resistance are more and more used in metalworking industry. This puts forward higher performance

indicators for the performance, spindle and structure of NC machine tools with ultra-high speed cutting and ultra-precision

technology, which should be fully considered in the selection of machine tools and control systems.

I. Requirements for Machine Tools in High Speed Cutting

- (1) The power of high-speed cutting machine tools must be large enough to meet the demand for the change of power and

- speed of machine tools during cutting.

- (2) High-speed cutting machine tools must be equipped with compact high-speed spindle and high-speed feed screw.

- (3) High-speed cutting machine tools must be equipped with solid bench, rigid gantry frame and the matrix material should

- have a greater effect on the structural vibration attenuation of machine tools. This structure can effectively eliminate the

- vibration in processing and improve the stability of machine tools.

- (4) The linear motor driven directly can improve the quality and greatly simplify the structure, and it is easy to achieve high

- linear speed and provide constant speed, so that the workpiece can obtain the best surface quality and longer tool life.

2. Requirements for NC in High Speed Cutting

For the CNC system of high-speed cutting machine tools, there must be high-speed and high-precision interpolation system,

fast response CNC system and high-precision system; there must be pre-reading, automatic angle deceleration, interpolation,

which can be applied to general computer platform and other functions.

3. Requirements for Spindle in High Speed Cutting

Because of the high speed of the spindle, high requirements are put forward for the structure and bearing of the spindle in

order to reduce the axial and radial circular runout of the spindle.

The integral manufacturing method can greatly reduce the

error of the spindle in high speed rotation. By choosing high precision bearings, the dynamic balance of the spindle can be

effectively improved and the error of the workpiece can be reduced.

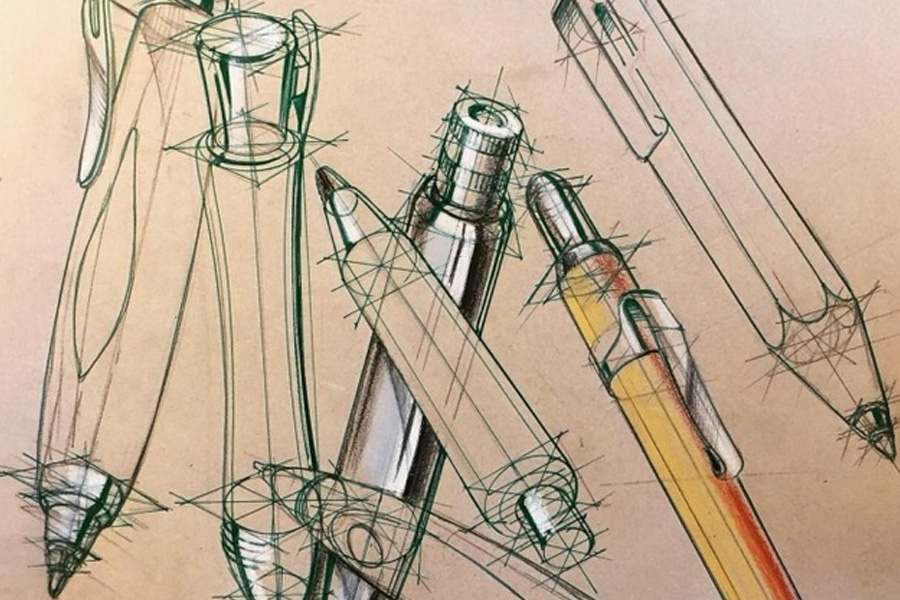

4. Requirements for Tools in High Speed Cutting

Tool selection is very important in high-speed cutting. Tool selection is mainly considered from two aspects: one is the dynamic

balance state of the tool under high-speed rotating state, and the other is how to ensure the life of the tool.

- (1) Cutting tools with dynamic balancing devices are used. Mechanical sliders or fluid dynamic balancing designs are installed

- in the tool sleeve.

- (2) The holistic cutter is adopted, and the cutter sleeve and the cutter body are integrated to ensure that the clearance between

- the cutter body and the cutter sleeve is minimum in the installation process. From the overall performance, the overall tool is

- the most ideal in this respect.

- (3) The General requirements of high-speed cutting tools are balance, advanced materials, high manufacturing accuracy, safety,

- easy chip removal and multi-purpose.

5. Requirements of High Speed Cutting for Parameters

When the spindle speed is fixed, first of all, attention should be paid to the control of cutting depth, including the axial cutting

depth of the tool and the radial cutting depth of the tool. The control of cutting depth plays a key role in producing a qualified

part and prolonging the service life of the tool.

Therefore, the stable cutting depth and the width of the comparative small

fluctuation range should be maintained. In general, cutting parameters should adopt higher cutting speed, less margin of

finishing time, more dense tool path and smaller cutting depth in order to obtain high accuracy and reduce the roughness of

the part surface.

6. Requirements for Programming in High Speed Cutting

In order to avoid the influence of machine inertia in high-speed cutting process, it is theoretically possible not to change the

direction of feed in the cutting process, but in fact it is impossible to achieve this. Changing the direction of feed is unavoidable

and often used, which gives programming a difficult problem. Therefore, it is necessary to select a suitable tool-walking

method to solve this problem in order to generate safe, effective and accurate tool paths and ideal surface accuracy.

Generally,

when the knife is empty, change direction as far as possible, and reduce the feed speed before changing the feed direction.

In addition, it is also very important to keep the cutting conditions as constant as possible. Because different tool loads can

cause tool deviation, which will reduce the accuracy of workpiece, surface accuracy and tool life.

SELECTION OF OIL PRODUCTS IN HIGH SPEED CUTTING

The factors affecting the accuracy of ultra-high speed cutting are roughly the cutting datum, the accuracy of cutting tools, the

rationality of cutting tool, the quality of workpiece raw materials, the performance of cutting oil and so on. How to select cutting

oil is also an important subject in metal cutting technology.

(1) Silicon steel cutting oil

Silicon steel is a relatively easy-to-cut material. Generally, in order to make the workpiece easy to clean, low-viscosity cutting

oil will be selected on the premise of preventing the occurrence of cutting burrs.

(2) Carbon steel cutting oil

When choosing cutting oil for carbon steel, the better viscosity should be determined first according to the difficulty and the

method of oil feeding and degreasing conditions.

(3) Stainless steel cutting oil

Stainless steel is easy to produce hardening material, which requires cutting oil with high film strength and good sintering

resistance. Cutting oil containing sulfur and chlorine compound additives is generally used to ensure extreme pressure

performance and avoid burrs and tool wear.

These are the technical schemes to realize high-speed cutting technology. With the continuous development of tool technology,

machine tool technology, programming technology, numerical control technology and other related technologies, high-speed

cutting technology will become more and more perfect and play an increasingly important role in modern manufacturing

industry.

Link to this article: What are the specific requirements for ultra-high speed metal cutting?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:What are the specific requirements for ultra-high speed metal cutting?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^