You need to pay attention to these 10 tips when modeling

| Not all models can be used for 3D printing. The online game character models are very beautiful, but in fact many can’t be used, why? Because the purpose of designer modeling is not for 3D printing, so Many places are not designed according to the requirements of 3D printing models. |

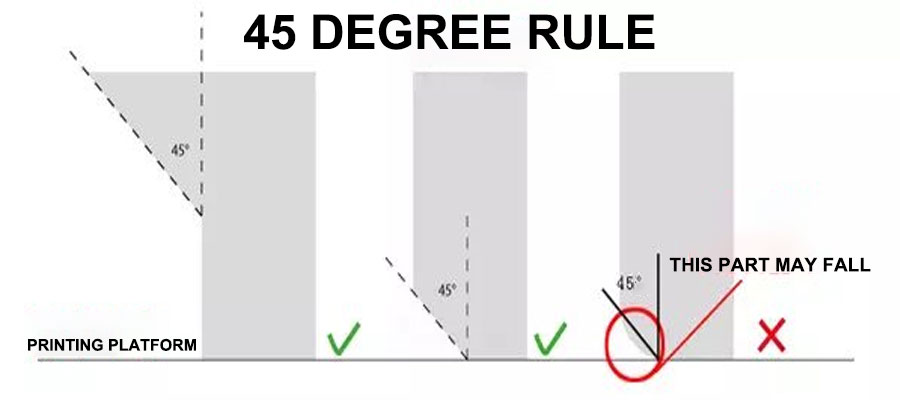

1. 45 degree rule

In the general model, more than 45 degrees of protruding parts need to be supported when printing. Therefore, when we are modeling, try to avoid the protrusion of a larger angle.

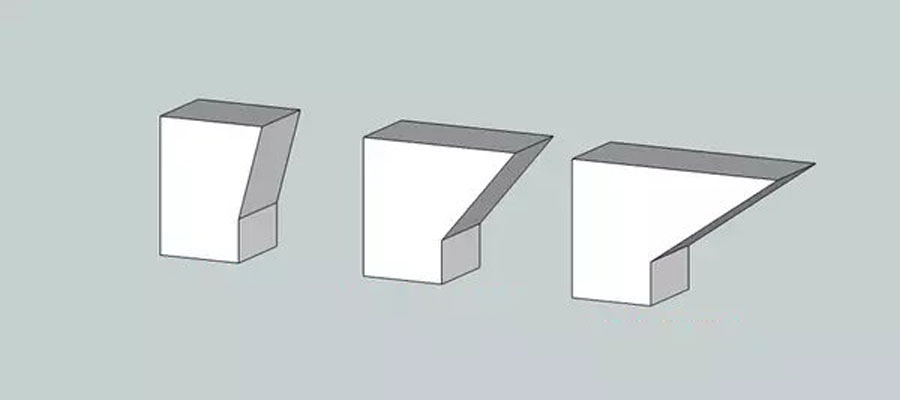

2. Optimize design with less support

The pain of support and support is only known after personal experience, and after the support is completed, it still leaves a very ugly mark on the model, and the process of removing the traces is time-consuming and laborious.

In fact, you don’t need to add support. When you look at modeling, you have to work harder. You can design support or joints for the parts that must be highlighted to reduce the chance of support.

This saves the trouble of adding support, supporting and polishing the support parts. Of course, the model can’t avoid the support, and it can only be added to the scalp.

3. Try to design your own print base

The large contact area between the bottom of the model and the platform can effectively reduce the curling edge, such as the most well-known “mouse ear”.

As shown below, this is a disc-shaped or conical base that increases grip.

Of course, you can also use the skirt and raft in the slicing software to reduce the curl. However, it is not recommended, it will drag down your printing time, and it is difficult to remove and damage the bottom of the model.

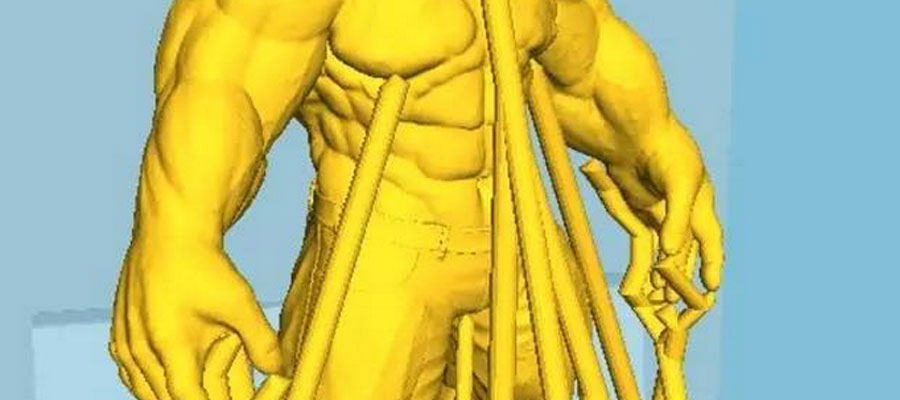

4. Understand the limits of your printer

According to the situation of your own printer, reasonable design of the model, such as using the FDM printer to print more detailed hand models, it is undoubtedly looking for bitterness, to support, trim corners….

In order to facilitate 3D printing, you need to pay attention to these 10 tips when modeling.

5. Reasonably set tolerances

The model printed by the ordinary desktop 3D printer has certain errors, especially moving parts, inner holes and the like.

For the higher precision requirements, the tolerance should be set reasonably when designing the model. For example, the inner hole gives the compensation amount. To find the right tolerance is more troublesome, you need to touch the “temper” of your machine.

6. Moderate use of the shell (Shell)

On some models with high precision requirements, don’t use too much when setting the shell, especially if the surface is printed with tiny characters. If the shell is set too much, it will blur these details.

7. Make good use of line width

When playing 3D printers, there is a very important but often overlooked variable, which is the line width. The line width is determined by the diameter of the printer nozzle, and most printer nozzles are 0.4mm in diameter.

When printing a model to draw a circle, the smallest circle that the printer can draw is twice the line width, such as a 0.4mm nozzle, the smallest circle that can be drawn, and the diameter is 0.8mm.

So make good use of the line width when modeling. If you want to make some models that can be bent or thinner, it is best to design your model thickness as a line width.

8. Adjust the print orientation for the best accuracy

For FDM printers, you can only control the accuracy (layer thickness) in the Z-axis direction because the accuracy of the XY-axis direction has been determined by the line width.

If your model has some fine design, it’s best to check if the print orientation of the model is capable of printing out the fine features. It is recommended to print these details in the Z-axis direction (vertically).

When designing the model, the details are also best placed in a position where it is easy to print vertically. It’s not working, you can cut the model to print and then reassemble.

9. Adjust the print direction to withstand the pressure

When the print needs to withstand a certain amount of pressure, you must ensure that the model will not be damaged or broken, and you will have to make a long-term impression when modeling and printing.

When modeling, you can appropriately thicken the position under pressure according to the direction of the force. When printing, printing is performed vertically in the Z-axis direction, and the adhesion between layers is limited, and the ability to withstand pressure is not as good as printing in the direction of the XY axis.

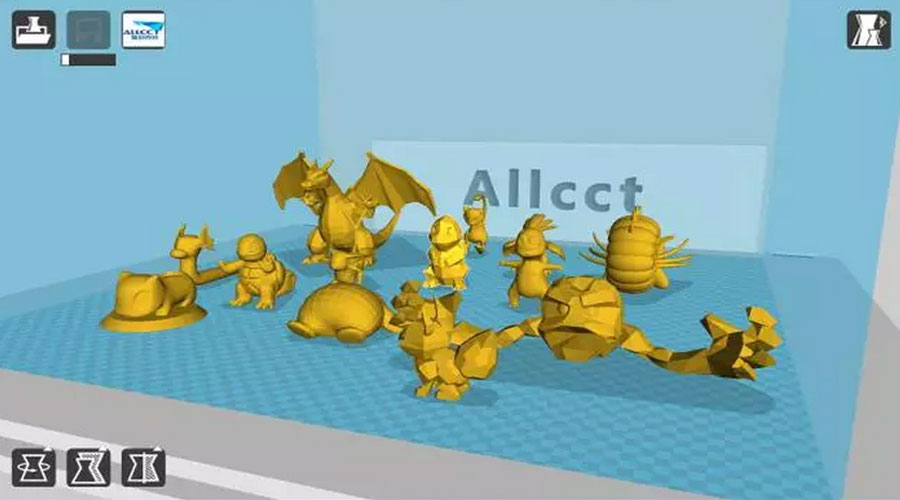

10. Place your model correctly

When printing, the placement of the model is also a university question. In addition to the adjustment of the printing direction mentioned above, you must pay attention to the placement position and minimize the chance of supporting.

Also, if a large number of models are printed together, the placement of the model needs to pay attention to the interval. It is not necessarily a good thing to get too close.

Link to this article: 10 tips to be aware of 3D printing modeling

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:10 tips to be aware of 3D printing modeling

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^