A few days ago, Peking University has developed a 3D printing device with independent intellectual property rights, and used the device to successfully prepare a multilayer PVDF-TrFE film. The coefficient and power density have been significantly improved. Related results are published online in “Energy and Environmental Science”.

Obtaining energy from natural resources such as mechanical strain, motion, light, heat, and magnetic fields has become a research hotspot in the fields of wearable, self-powered electronics, and wireless sensor networks (WSNs) of the Internet of Things. Energy harvests mechanical strain and movement. The traditional methods include piezoelectric, electrostatic and electromagnetic. However, as a typical self-powered, self-sensing wearable device, the piezoelectric energy harvester exhibits the advantages of simple structure, miniaturization, and higher energy density. Compared with traditional inorganic ceramics and single crystal materials, PVDF and its copolymers are more suitable for wearable electronics and walking power generation due to its flexibility, flexible design, small acoustic impedance, wide response frequency and high chemical stability. And other applications. However, compared with inorganic piezoelectric ceramics or piezoelectric single crystals, due to its small piezoelectric coefficient and dielectric constant, the generated power density has always been low.

Recently, the research group of Professor Dong Shuxiang from the School of Engineering of Peking University has developed a 3D printing device with independent intellectual property rights under the special funding of Beijing Municipal Science and Technology Project, and obtained the authorization of Chinese invention patents. They used their self-developed 3D printing equipment to successfully prepare a multilayer PVDF-TrFE film, and developed a piezoelectric energy harvester with a novel rugby structure with flex-tension effect. Its apparent piezoelectric coefficient and power density have been significantly improved.

Experimental results show that the 3D printed football energy harvester can generate a peak voltage of 88.6Vp-p and a short-circuit current of 0.35mA under a mechanical pressure of 3.5HZ frequency and 0.046MPa pressure. Its peak output power density per unit area is as high as 16.4mW/cm 2, which is an order of magnitude higher than the power density of other flexible piezoelectric power generation materials and is equivalent to the power density of solar cells. The 3D printing multilayer flexible piezoelectric film preparation method and the energy harvesting design of the football bending and tension mechanism proposed by Dong Shuxiang’s research group will be flexible wearable electronic devices with self-sensing and self-powered functions, wireless sensor networks, and self-powered smart roads in the future. In other aspects, it has great potential for development.

This research result also proves that the 3D printing process is a simple and effective method and has application prospects in the field of flexible and microelectronic device preparation in the future.

The first author of the paper is Yuan Xiaoting, a 2017 doctoral student in the Department of Materials Science and Engineering, Peking University, and Dong Shuxiang is the only corresponding author of the paper. This research was funded by the National Natural Science Foundation of China (51772005, 51132001), the Beijing Municipal Science and Technology Project, the Beijing Key Laboratory of Magnetoelectric Functional Materials and Devices, and ENN Energy Technology.

Link to this article: 3D printing equipment prepares high power density flexible piezoelectric energy recovery device

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

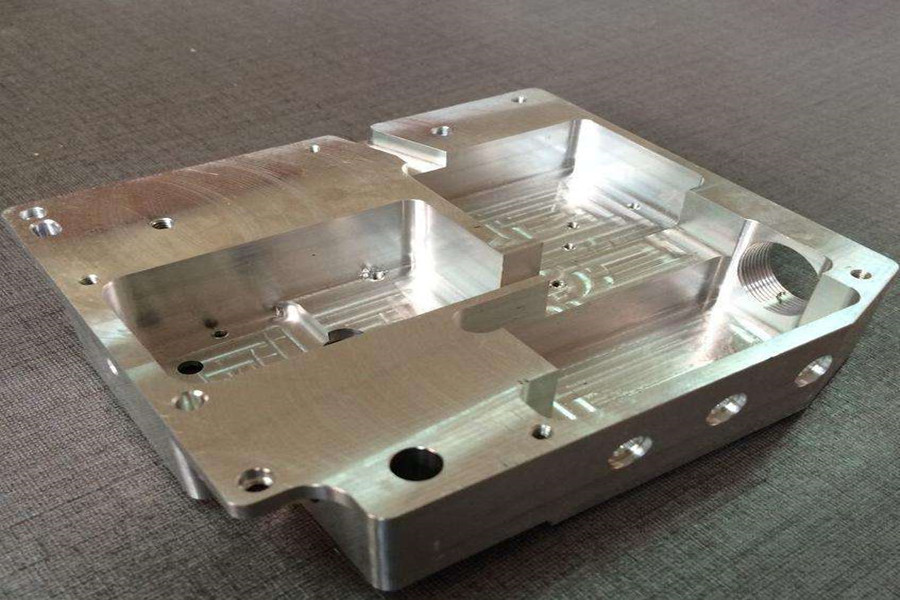

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

Machining shop specializing in fabrication services for construction and transportation industries. Capabilities include plasma and oxy-fuel cutting, Tailored machining, MIG and Custom Aluminum Cnc Precision Milling Welding Jig Fixture, roll forming, assembly, Lathe machining stainless steel cnc machine shaft, shearing, and CNC Swiss Machining services. Materials handled include carbon and Passivation Stainless Steel Machining Cover Plate Parts.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

Link to this article:3D printing equipment prepares high power density flexible piezoelectric energy recovery device

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^