Notice: Undefined index: sith_post_head in /www/sites/alloy.wiki/index/wp-content/themes/likegoogle/includes/single-head.php on line 4

Notice: Undefined index: sith_post_head in /www/sites/alloy.wiki/index/wp-content/themes/likegoogle/includes/single-head.php on line 9

Notice: Undefined index: sith_post_head in /www/sites/alloy.wiki/index/wp-content/themes/likegoogle/includes/single-head.php on line 14

Notice: Undefined index: sith_post_head in /www/sites/alloy.wiki/index/wp-content/themes/likegoogle/includes/single-head.php on line 29

Notice: Undefined index: sith_post_head in /www/sites/alloy.wiki/index/wp-content/themes/likegoogle/includes/single-head.php on line 36

Notice: Undefined index: sith_post_head in /www/sites/alloy.wiki/index/wp-content/themes/likegoogle/includes/single-head.php on line 50

Notice: Undefined index: sith_post_head in /www/sites/alloy.wiki/index/wp-content/themes/likegoogle/includes/single-head.php on line 67

Notice: Undefined index: sith_post_head in /www/sites/alloy.wiki/index/wp-content/themes/likegoogle/includes/single-head.php on line 78

Deprecated: get_settings is deprecated since version 2.1.0! Use get_option() instead. in /www/sites/alloy.wiki/index/wp-includes/functions.php on line 4862

Inconel is an austenitic nickel-chromium based superalloy with specific applications. Inconel has several features, such as resistance to corrosion, oxidation, and the ability to withstand high temperatures, making it the perfect material for extreme environments. Inconel has high temperature strength due to solid solution strengthening or precipitation strengthening. This material is also pressure resistant, making it ideal for extreme applications.

Inconel (ALLOY) has many excellent properties. First, it has excellent strength and hardness at high temperatures and can maintain good mechanical properties in high temperature environments. Secondly, it has good corrosion resistance and can be used in various corrosive environments. In addition, Inconel (ALLOY) also has good oxidation resistance and fatigue resistance, and can resist the influence of various environmental factors.

Some High Temperature Alloy Types:

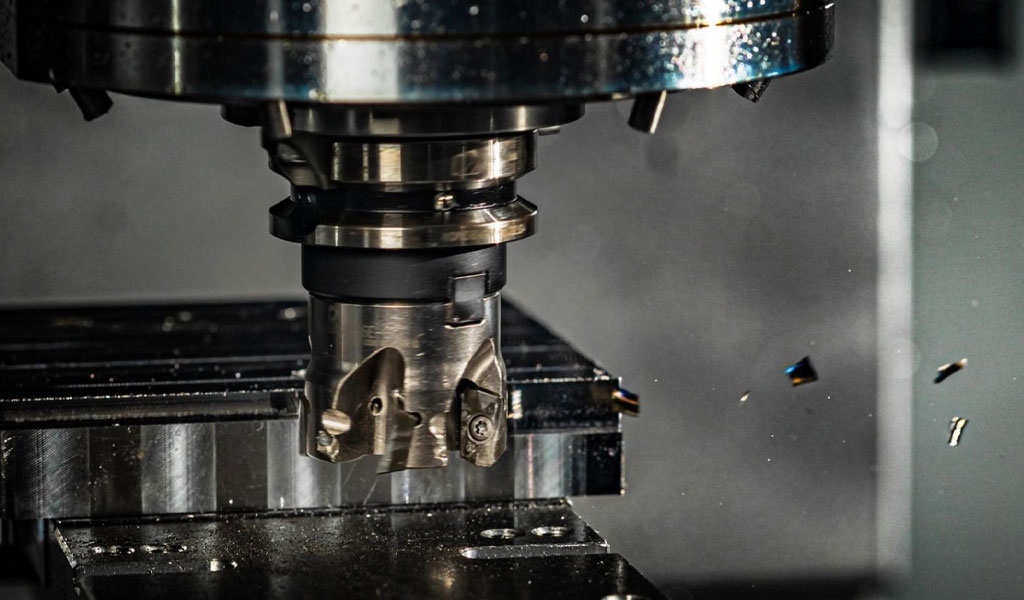

- 1.Inconel 600: The nickel content is 72%, the chromium content is 14%-17%, and it also contains molybdenum, cobalt, iron and other elements. Mainly used in inconel cnc machining, chemical processing and electrical fields at high temperatures.

- 2.Inconel 718: The nickel content is 50%, the chromium content is 17%-21%, and it also contains titanium, niobium and other elements. It is the most commonly used Inconel alloy and is suitable for aerospace, petrochemical, nuclear industry and other fields.

- 3.Inconel X-750: The nickel content is 70%, the chromium content is 14%-17.5%, and it also contains niobium, titanium and other elements. Suitable for manufacturing springs, valves, bearings and other components under high temperatures.

- 4.Inconel 625: The nickel content is 58%, the chromium content is 20%-23%, and it also contains iron, aluminum, molybdenum, titanium and other elements. Suitable for manufacturing corrosion-resistant materials in seawater environments and nozzles and other components under high temperatures.

- 5.Inconel 601: The nickel content is 61%, the chromium content is 22%-25%, and it also contains aluminum, titanium and other elements. Suitable for parts manufacturing in oxidation, corrosion and wear environments at high temperatures.

The Application Fields Of High Temperature Alloys

We will discuss 5 main applications of Inconel alloys:

Aerospace And Jet Engines

Nickel alloys are a natural alternative for the aerospace industry. Engine components, in particular, are exposed to high temperatures and pressures. Materials must be able to withstand this environment and maintain their strength and integrity. Nickel alloys are creep resistant under high stress conditions, show low expansion at these high temperatures, and are corrosion resistant.

For example, Inconel 600 is used in jet engines and airframe parts such as exhaust liners, lock lines and turbine seals. And Inconel 601 is used in various aerospace technologies because it can withstand stress and is very easy to use.

Oil And Gas Extraction

Oil and gas extraction is one of the main industrial applications of Inconel alloys. When it comes to material selection, design engineers evaluate many factors in oil and gas extraction because of the high temperatures and the flammable and corrosive nature of the raw materials being processed or stored.

Inconel 625 is one such superalloy used to separate extracted liquids in processing systems for LNG manufacturing. Inconel alloy 625 has excellent fatigue and thermal fatigue strength, oxidation resistance, high creep, tensile strength and fracture resistance as well as excellent weldability. It is commonly used to line steel transmission pipelines in sour gas and natural gas extraction facilities.

Pollution Control And Waste Disposal

Working in environments such as pollution control and waste disposal is difficult, so materials need to work hard. Naturally hazardous and corrosive materials require deposition, movement and handling. Therefore, alloys used in waste treatment systems must have excellent resistance to reducing acid solutions and oxidation, as well as to the high temperatures involved in operation, without losing structural integrity or strength.

One such alloy is Inconel C-276, which offers excellent corrosion resistance in such environments. This alloy contains high levels of molybdenum (15-17%), making it resistant to pitting and crevice corrosion. Its low carbon content minimizes carbide precipitation during welding to ensure it remains corrosion resistant in welded structures.

Car And Automotive

Car engines are delicate beasts that generate a lot of heat, but need to be reliable and weigh less. As the automotive industry advances, engineers continue to source materials that match technological developments and push to deliver the “next big thing” in the automotive sector. In addition to more power and thrust, car engines also need to save fuel and control pollution levels.

Therefore, it is necessary to choose the right material. Inconel alloy 625 can be used in this area as it is one of the most versatile materials. High performance cars and supercars often use Inconel 625 for exhaust couplings. Inconel alloys are also used in sensors, safety devices, ignition systems and electrical switchgear.

Marine Industry

Inconel alloys are used in many seawater applications. On offshore platforms, or in power and process plants that use seawater as coolant. Seawater systems are highly corrosive in nature, so it is necessary to use materials that will not degrade under these conditions.

Inconel alloy performs well in this extreme situation. For example, Inconel 625 is used in propeller blades, propulsion motors, wire ropes and undersea communications cable jackets. Other uses for the Inconel alloy range include platform risers, hangers, downhole equipment and high-strength fasteners.

Inconel (ALLOY) is widely used in the aerospace field. Because the alloy has excellent corrosion resistance and high-temperature strength, it can be used to manufacture key components such as high-temperature parts of aircraft engines and combustion chambers of rocket engines. In addition, Inconel (ALLOY) can also be used to manufacture corrosion-resistant parts in petrochemical equipment, such as pipes, valves, etc. In the field of automobile manufacturing, Inconel (ALLOY) can be used to manufacture components such as exhaust systems and turbochargers to improve their performance and durability.

Inconel (ALLOY) has a wide range of applications. In addition to aerospace, petrochemicals and automobile manufacturing, it can also be used in electronics, environmental protection and other fields. With the continuous advancement of science and technology and the continuous development of the industrial field, the application prospects of Inconel (ALLOY) will be broader.

Link to this article:Inconel Alloy

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^