|

|

|

|

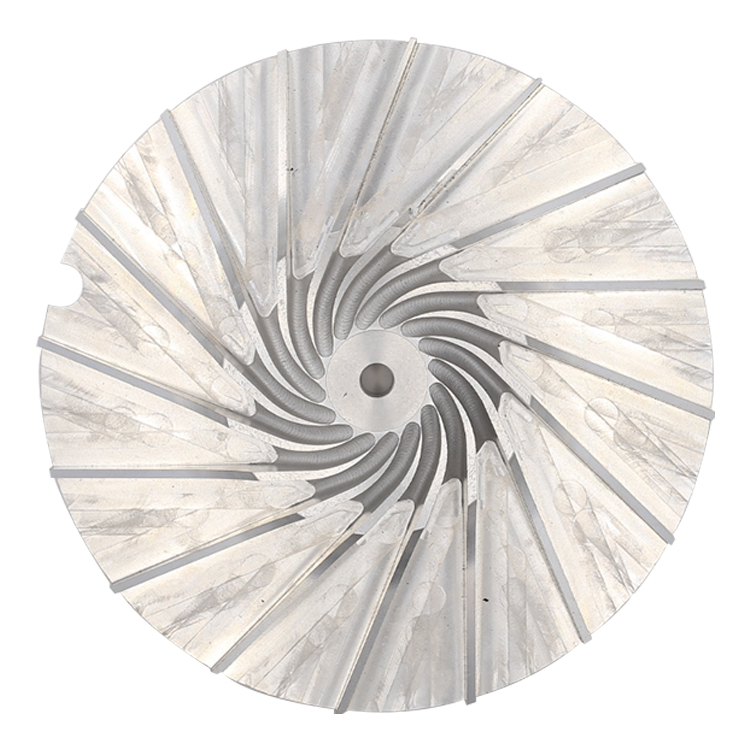

Aluminum alloy CNC MachiningAluminum alloy introduction: Aluminum alloy is one of the most widely used non-ferrous metal structural materials in the industry and has been widely used in aviation, aerospace, automotive, machinery manufacturing, marine and chemical industries. The density of pure aluminum is small (ρ=2.7g/cm3), which is about 1/3 of iron. The aluminum alloy has low density, but high strength, close to or exceeds high-quality steel, good plasticity, can be processed into various profiles, has excellent electrical conductivity, thermal conductivity and corrosion resistance. It is widely used in industry and is used second only to steel. . The aluminum alloy has low density, but high strength, close to or exceeds high-quality steel, good plasticity, can be processed into various profiles, has excellent electrical conductivity, thermal conductivity and corrosion resistance. It is widely used in industry and is used second only to steel. . |

Link to this article: Aluminum alloy cnc machining application

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:Aluminum Genus :Aluminum alloy cnc machining application

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^