3D printing technology in automobile R&D and production

| In recent years, 3D printing technology has been widely used in various fields, including industrial, aerospace, military, medical and so on. Especially in the automotive industry, many different 3D printing technologies have been iterated. |

At present, the application of 3D printing in automobiles is mainly concentrated on research and development, and there is no application in mass-produced automobiles. This is mainly because the production of bulk parts for automobiles is currently dominated by molds, because in the case of mass production, the cost per piece of the mold is lower and the molding efficiency is higher. In addition, there is still a gap between the performance of 3D printed materials and the requirements of people.

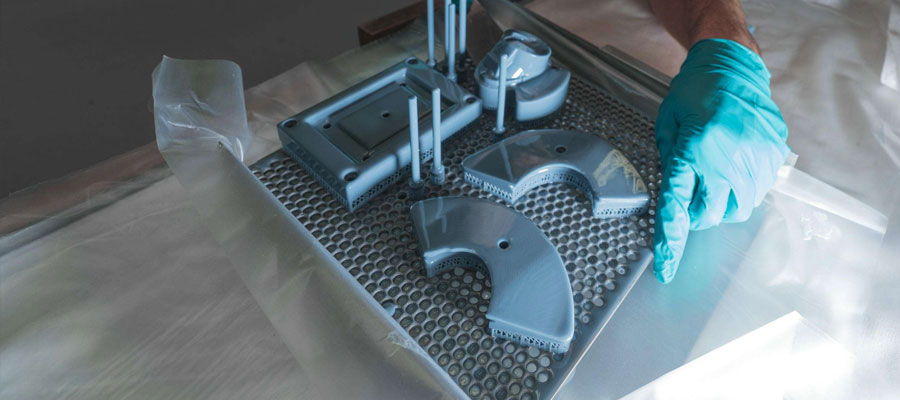

The application examples of 3D printing in automobile R&D and production mainly include design data matching verification, part modeling display, prototype car loading, tool fixtures, metal inserts and functional tests. Corresponding 3D printing technologies include SLA, SLS, MJF, FDM, SLM, Polyjet, and sand printers.

- ▶ SLA:low price,big size,high parts surface quality,low impact resistance,Low viscosity

- ▶ SLS/MJF:high price,medium size,low parts surface quality,high impact resistance,medium viscosity

- ▶ FDM:low price,big size,medium parts surface quality,medium impact resistance,high viscosity

- ▶ POLYJET:medium price,medium size,high parts surface quality,medium impact resistance,high viscosity

- ▶ SLM:high price,small size,low parts surface quality,high impact resistance,welding

- ▶ Sand printer:high price,big size,low parts surface quality,medium impact resistance,high viscosity

The reason why so many technologies are produced is because different technologies always produce different advantages and disadvantages. So far, no technology has been available in one step. For example, SLA, FDM, and sand printers can print large parts, while SLM can only print small parts.

From the surface quality of parts, SLA is higher, SLS and SLM are lower, and sand type The printer is the worst; from the impact resistance of molded parts, SLS, SLM is higher, SLA is lower; from the perspective of bonding performance, FDM, sand printer is better, SLA is worse. See the table above for details.

These properties are primarily related to the materials used in different 3D printing technologies. Plastic materials such as photosensitive resins are used for SLAs, so they are still not ideal for impact resistance and high temperature resistance.

SLA technology is not ideal for impact resistance and high temperature resistance at this stage, but it is an indispensable technology in rapid prototyping print samples.

Link to this article: Application of 3D printing technology in automobile R&D and production

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:Application of 3D printing technology in automobile R&D and production

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^