Notice: Undefined index: sith_hide_share in /www/sites/alloy.wiki/index/wp-content/themes/likegoogle/single.php on line 32

Deprecated: get_settings is deprecated since version 2.1.0! Use get_option() instead. in /www/sites/alloy.wiki/index/wp-includes/functions.php on line 4862

The good spraying effect of mold lubricant is the key factor to obtain good casting surface quality. However, the existing spraying methods often fail to take into account the entire cavity surface, and there are often cases of poor spraying, local mold sticking, and strains.

This problem can be effectively solved by developing and using in-mold spraying technology. This internal spraying device is only composed of a spraying pipe designed inside the mold and an atomizer. It is characterized by making full use of the original pipeline and control unit on the die-casting machine. One end of the atomizer is directly connected to the paint pipe and air pipe of the spraying manipulator. Unicom, the other end is connected with the inlet of the inner spraying pipe on the mold, which realizes the synchronous action with the spraying manipulator on the die-casting machine. The actual verification shows that the use of internal spraying technology greatly reduces the casting rejection rate and ensures the stability of the production process.

1 Common spraying methods and existing problems

Sticking of castings is a common die casting defect. There are many reasons for the defects. Usually, it can be analyzed and improved from the spraying of mold lubricant, the arrangement of cooling water channels, the feeding method, and the Alloy composition.

At present, most domestic manufacturers use the linkage of spraying manipulators and machine tools to complete the spraying and blowing actions on the mold. Some manufacturers also use manual spraying for production, the spraying time and location are more flexible, and the production cycle is fast. In contrast, the reliability of automatic spraying will be better, and the quality of castings will be stable. The manual method usually relies on more experienced workers to operate.

In the production of molds on larger tonnage (above 8000kN) die-casting machines, a combination of two methods is often used for spraying to achieve a good demolding effect. Servo spraying and smart spraying are also gradually adopted by everyone, with better results.

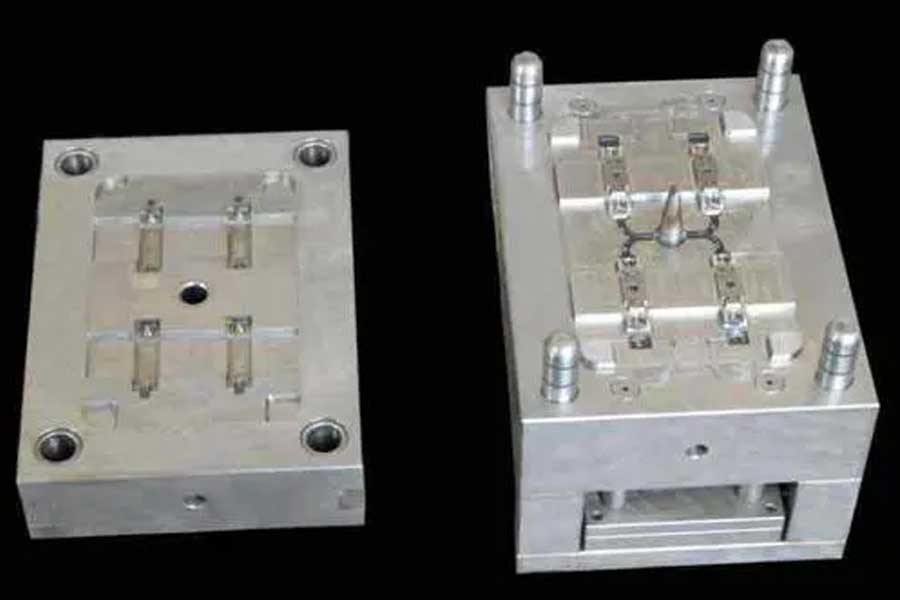

Due to the structure of the casting, part of the mold often adopts such a design as shown in Figure 1 and Figure 2. After a certain core is pulled out, the core forming part is hidden in the lining mold or a certain slider block, and the coating cannot be sprayed. In order to improve the spraying effect of this type of core, whether it is a diagonal rod or a hydraulic core-pulling method, the size of the core matching hole is mostly enlarged to enlarge the paint entering the gap. This method has a certain improvement effect, but the spraying effect is still not particularly ideal. With reference to the core pulling function of the oil cylinder, for the hydraulic core pulling slider, the concept of core spraying is proposed, that is, during the automatic spraying process of the die-casting machine, the program setting is changed to realize the spraying after the core. On this basis, at present, two major domestic die-casting manufacturers have modified the die-casting machine program and successfully achieved this action.

When the core-pulling method is diagonal rod core-pulling, the above method cannot be realized. Because it can not be sprayed by changing the die casting machine program. To solve this problem, an in-mold spraying technology was developed.

2 Principle of spraying in the mold

The principle of the spraying technology in the mold is relatively simple, that is, the paint pipeline is built in the mold, and the outside is connected with the automatic proportioning device of the release agent, and the automatic control of the electrical unit realizes the timing and fixed-point spraying. Since the outlet of the paint pipe is set inside the mold, the choice of location is very flexible, which makes up for the shortcomings of the above-mentioned spraying process and effectively solves this problem.

There are generally two ways to arrange the outlet of the spraying pipe in the mold. One is on the slide. The principle of action is: when the slider is pulled in place, the paint port is exposed and spraying is carried out, as shown in Figure 3a; after the slider is in place, the paint The mouth is closed, see Figure 3b. The other is arranged on the ejector pin of the mold and is rarely used.

3 Internal spraying device and internal spraying plan

The whole set of internal spraying device generally includes the following parts: one is the spraying pipeline designed inside the mold; the other is the atomization device similar to the spraying manipulator on the die-casting machine; the third is the independent electrical control unit. The linkage between the atomization device and the die-casting machine is realized through the setting of the electric unit, so as to realize the internal spraying of the mold.

This kind of internal spraying solution requires more components to be combined together. For example, an atomization device usually requires solenoid valves, pressure reducing valves, flow control valves, atomizers, etc. to act together in series. The electrical control unit is an independent electrical cabinet, which is connected to the die-casting machine’s signal. It is necessary to set the blowing, spraying and delay actions. This mechanism is placed next to the die-casting machine when it is working, and can be moved. However, it occupies a certain amount of work space, and also requires a certain amount of capital investment. The connection between the device and the machine tool is also complicated, which brings inconvenience to the operation of the workers and is difficult to implement. Need to be further simplified for implementation.

It can be seen that the spraying pipeline inside the mold has different opening methods due to different castings, but it cannot be simplified. The atomization device and electrical control unit can be simplified by borrowing the original control module on the die-casting machine.

According to this idea, a set of spraying scheme in the mold was newly developed, as shown in Figure 4. The parts in the dashed frame are all borrowed from the original parts of the die-casting machine. It consists of only a spray pipe designed inside the mold and an atomizer. One end of the atomizer is directly connected with the paint pipe and air pipe of the spraying manipulator, and the other end is connected with the inlet of the inner spraying pipe on the mold to achieve synchronization with the spraying manipulator on the die-casting machine.

During use, the atomizer is fixed on the mold through a transition block, which not only achieves a good spraying effect, but is also compact and convenient. The entire die-casting workshop can be equipped with several atomizers according to the situation. The left and right sides of the die-casting machine are reserved for paint and compressed air interfaces for convenient use.

4 Application examples of internal spraying

Internal spray application example: a valve body leakage improvement, see Figure 5.

The net weight of the valve body parts is about 1770g, the maximum external dimension is 155mm×205mm×103mm, the minimum wall thickness is 2.5mm, and the maximum wall thickness is 33mm. During the production process, the upper slider part (inside the circle) of the casting was severely strained, causing leakage. Four internal spray outlets were added to the slideway of the slider on the mold, and the leakage defect caused by the casting strain has been greatly improved, as shown in Figure 6.

5 Conclusion

The development of spraying technology in the mold provides a new technical means to solve the problem of casting sticking. This structure makes full use of the original pipeline and control unit on the die-casting machine, has a simple structure and is convenient to disassemble, and has also been popularized and applied on other die-casting molds, and has achieved good results.

Link to this article: Development and Application of Spray Technology in Die Casting Mould

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

Link to this article:Development and Application of Spray Technology in Die Casting Mould

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^