Notice: Undefined index: sith_hide_share in /www/sites/alloy.wiki/index/wp-content/themes/likegoogle/single.php on line 32

Deprecated: get_settings is deprecated since version 2.1.0! Use get_option() instead. in /www/sites/alloy.wiki/index/wp-includes/functions.php on line 4862

A few months ago, a team from the Wyss Institute at Harvard University developed an engineering solution, SWIFT, dedicated to making 3D printed organs more viable. With it, researchers can create synthetic perfusion heart tissue that can beat synchronously for seven days. Now, the same team has made new progress in the field of 3D printing.

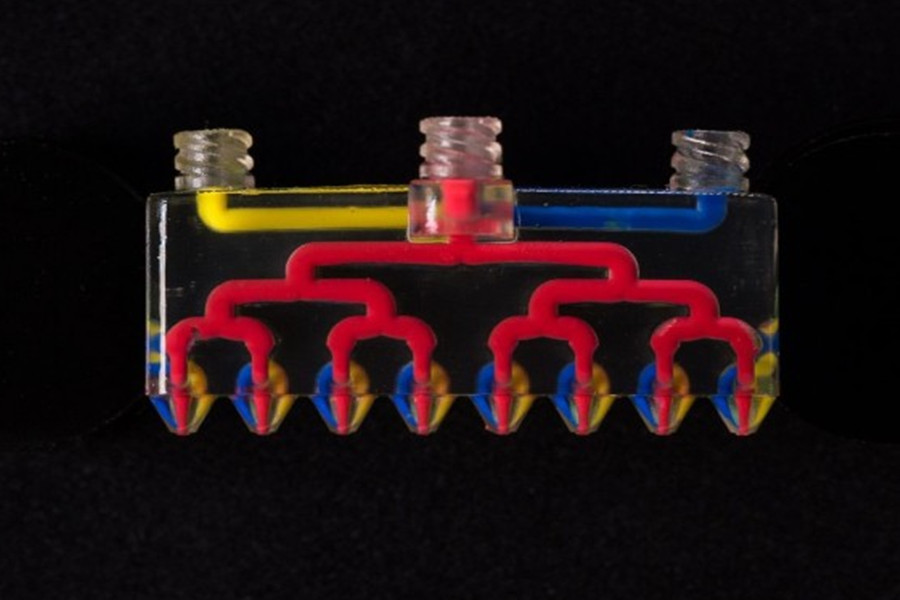

Researchers at the Wyss Institute have developed a technique that obviously can significantly speed up the production of complex 3D printed objects. This technology is called multi-material multi-nozzle 3D printing (MM3D), and it uses a high-speed pressure valve to seamlessly switch between eight different printing materials to create complex shapes and objects. According to the team, each valve “can switch materials up to 50 times per second, which is faster than the naked eye can see, or as fast as a hummingbird flapping its wings.”

Subsequently, this will speed up the printing process. The team claims that MM3D requires only a fraction of the time to create such objects using traditional methods (including the use of single nozzles and large multi-nozzle print heads).

The key element of this technology is a set of Y-shaped connection points, which are precisely adjusted to prevent ink mixing or backflow during printing. For printing large objects, these nodes can be multiplexed. Specifically, this rapid unidirectional continuous ink flow can use reactive materials such as silicone, polyurethane, epoxy, or bio-ink to accurately construct complex parts.

Skylar-Scott’s team demonstrated the MM3D technology by printing Miura origami structures. The structure consists of a rigid “panel” part connected with a highly flexible “hinge” part. Unlike traditional methods that require a lot of time and multi-layer processing, “MM3D print heads can continuously extrude two alternating epoxy resin inks by using eight nozzles. After one step, they can continuously print two epoxy resins whose stiffness differs by four orders of magnitude. Resin ink to print the entire object step by step.”

The researchers also used MM3D to print a walking “soft robot in the shape of a millipede, which is composed of a robotic arm and a soft elastic body.” What is impressive is that “the robot can move at a speed of nearly half an inch per second, while carrying eight times its own weight, and can be connected with other robots to carry heavier loads.”

Currently, MM3D can only print periodic, patterned objects. But the Wyss team believes that with further development and research, the team will allow the process to create even more complex structures in one step. All in all, Donald Ingber, the founding director of Wyss, saw the potential of manufacturing technology and pointed out that “this new development [MM3D] is expected to greatly improve the pace of innovation in this exciting field.”

Link to this article: New progress has been made in the field of 3D printing!

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

Machining shop specializing in fabrication services for construction and transportation industries. Capabilities include plasma and oxy-fuel cutting, Tailored machining, MIG and Custom Aluminum Cnc Precision Milling Welding Jig Fixture, roll forming, assembly, Lathe machining stainless steel cnc machine shaft, shearing, and CNC Swiss Machining services. Materials handled include carbon and Passivation Stainless Steel Machining Cover Plate Parts.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

Link to this article:New progress has been made in the field of 3D printing!

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^