Notice: Undefined index: sith_hide_share in /www/sites/alloy.wiki/index/wp-content/themes/likegoogle/single.php on line 32

Deprecated: get_settings is deprecated since version 2.1.0! Use get_option() instead. in /www/sites/alloy.wiki/index/wp-includes/functions.php on line 4862

A new study found that the purity of graphene may be an obstacle to the wide application of this new material. Reducing silicon pollution in graphene is expected to improve its performance and give full play to the application potential of graphene in the industry.

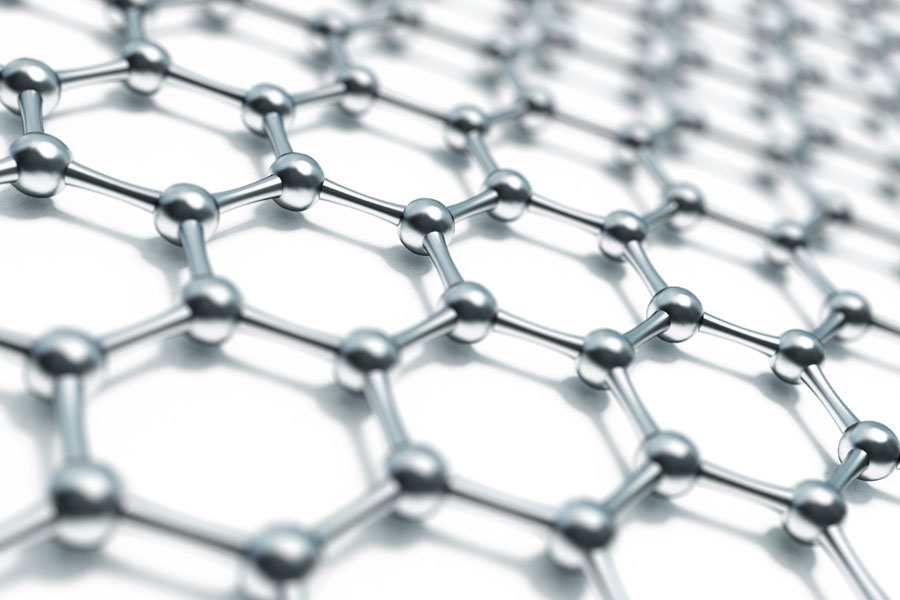

Graphene is a two-dimensional material composed of a layer of carbon atoms separated from graphite materials. It has the properties of lightness, thinness, toughness, high electrical conductivity and high thermal conductivity, and is a new-generation material that is highly expected by the industry. However, the actual performance of graphene is not satisfactory, and the speed of popularization in the industry is not ideal.

A team led by researchers from the Royal Melbourne Institute of Technology in Australia reported in the journal Nature Communications that they used the most advanced scanning transmission electron microscope to conduct an atomic-level detailed inspection of commercial-grade graphene samples on the market and found that The degree of silicon pollution is very high, and this has a great influence on the performance of graphene. For example, the performance of contaminated graphene as an electrode can be 50% lower than the theoretical expected value.

In a telephone interview with Xinhua News Agency reporters, Langhera Ali Jalili, who participated in the research, said that since graphene has only one layer of atoms, it is particularly susceptible to surface pollution, and silicon pollution makes graphene performance unstable, making it difficult. Establish an industry standard to regulate the performance indicators of graphene.

Further experiments found that although it is difficult to directly remove silicon contamination in graphene, as long as the raw material for preparing graphene-the silicon component in graphite, it is easier to obtain high-purity graphene. Researchers use this method to prepare high-purity graphene, and use them to make large-capacity batteries, as well as extremely sensitive humidity sensors, confirming the excellent performance of high-purity graphene.

Link to this article:New research finds ways to improve the properties of graphene materials

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

Link to this article:New research finds ways to improve the properties of graphene materials

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^