Notice: Undefined index: sith_hide_share in /www/sites/alloy.wiki/index/wp-content/themes/likegoogle/single.php on line 32

Deprecated: get_settings is deprecated since version 2.1.0! Use get_option() instead. in /www/sites/alloy.wiki/index/wp-includes/functions.php on line 4862

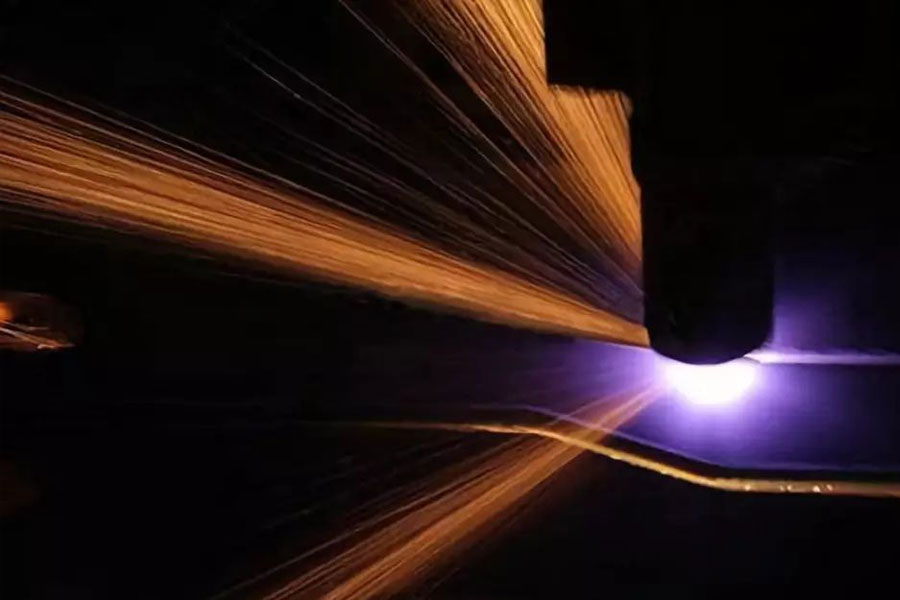

What is the difference between laser welding technology and robot welding? With the continuous development of welding technology, various welding processes have begun to develop. Among them, laser welding technology is widely used in various fields. Laser welding has the advantages of high energy density, small deformation, and fast welding speed.

This article will take you to understand laser welding The difference between technology and robotic welding.

- 1. The welding accuracy is different. The welding position of laser welding needs to be accurately welded, and the welding work needs to be carried out within the focus range of the laser beam, which can reach 0.1mm, the welding accuracy is very high, and some parts with small spacing can be welded; most of the robot welding is The way of teaching and reproducing requires setting the welding program, including welding speed, welding spot position, etc., and different programming is required for different welding seams.

- 2. The specifications of welding materials are different. Laser welding is suitable for thin materials and thin wire welding. The thickness that can be welded is limited. It cannot weld workpieces over 19mm. Laser welding is not suitable for production lines. Robot welding does not require particularly high overall dimensions. The welding robot has deviation sensing and The arc tracking function in the welding process, so the workpiece with different thickness will be compensated during the welding process.

- 3. Different welding methods. During laser welding, the welding torch does not need to use electrodes, there is no worry about electrode contamination and replacement of the welding torch, and non-contact welding can be used, and the wear and deformation of related parts can be reduced; the robot welding achieves contact welding, and the welding torch is required as a wearable part. Regular replacement, and the welding gun needs to be cleaned during work, which affects the work process.

- 4. The welding environment is different. Both laser welding and robot welding can work in harsh environments. Laser welding can work in a vacuum environment; robot welding can be customized according to different use environments.

- 5. The welding quality is different. Laser welding has a fast local heating speed, small impact on peripheral components, and small welding deformation. Robot welding is fixed with tooling fixtures, and certain measures need to be taken to reduce the deformation of the workpiece.

Link to this article: The Difference Between Laser Welding And Robot Welding

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include Aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include Aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

Link to this article:The Difference Between Laser Welding And Robot Welding

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^