The importance of pipelines is self-evident. As an effective material transportation method, it is widely used in urban rainwater and sewage, natural gas transportation, industrial material transportation, water supply and drainage, and ventilation systems such as buildings. In order to improve the life of the pipeline, prevent leakage and other accidents, and ensure the normal operation of the pipeline, it is necessary to carry out effective inspection and maintenance of the pipeline. As a fast and safe inspection method, pipeline inspection robots are increasingly used In terms of pipeline inspection.

Next, this article will focus on the types of pipeline robots, so that everyone has a clearer understanding of them.

At present, there are many types of pipeline robots developed at home and abroad. According to the energy supply mode, they can be divided into two types: cabled and non-cabled.

For pipeline robots powered by cables, the main problem is that when the robot travels a long distance and turns more, the friction between the cable and the pipe wall will become very large, which seriously affects the maximum walking distance of the robot during operation. It will also bring a series of problems such as reliability.

At present, there are two solutions for the use of cable-free energy supply. One is to carry batteries, and the other is to carry fuel generator sets. In addition to the common shortcomings of bulkiness and increased weight of the robot body, these two solutions also include storage. After all, the energy of the robot is limited, and is affected by factors such as battery quality and charging technology, so the walking distance of the robot is still limited.

The driving source of the pipeline robot is roughly as follows: micro motor, piezoelectric drive, shape memory Alloy (SMA), pneumatic drive, magnetostrictive drive, electromagnetic conversion drive, etc.

Pipeline robots can be roughly divided into self-driving pipeline robots, fluid-propelled pipeline robots, and elastic rod plus thrust-type pipeline robots according to the driving mode.

Pipeline robots can be divided into three types: large, ordinary and micro according to their size. Among them, micro-pipe robots can be divided into sine wave-driven micro-pipe robots, electromagnetic-driven pipeline fin robots, and micro-pipe robots according to their electric drive technology. Snake robots driven by DC motors, micro-pipe robots driven by piezoelectric elements, micro-pipe robots driven by GMA, and earthworm peristaltic pipeline robots driven by SMA.

What types of pipeline robots can be divided into?

If divided by the walking mechanism, the pipeline robot can be divided into the following ways:

- (1) Piston movable type, its principle is similar to the movement of piston in the cylinder, that is, the pipe is regarded as the cylinder, and the PIG with certain elasticity and hardness is regarded as the piston. Structurally, when the fluid pressure behind the PIG is greater than the front pressure, under the action of the pressure difference, the PIG overcomes the frictional resistance between the pipe wall and the piston and moves forward. PIG can carry a variety of sensors and use it for pipeline detection while walking.

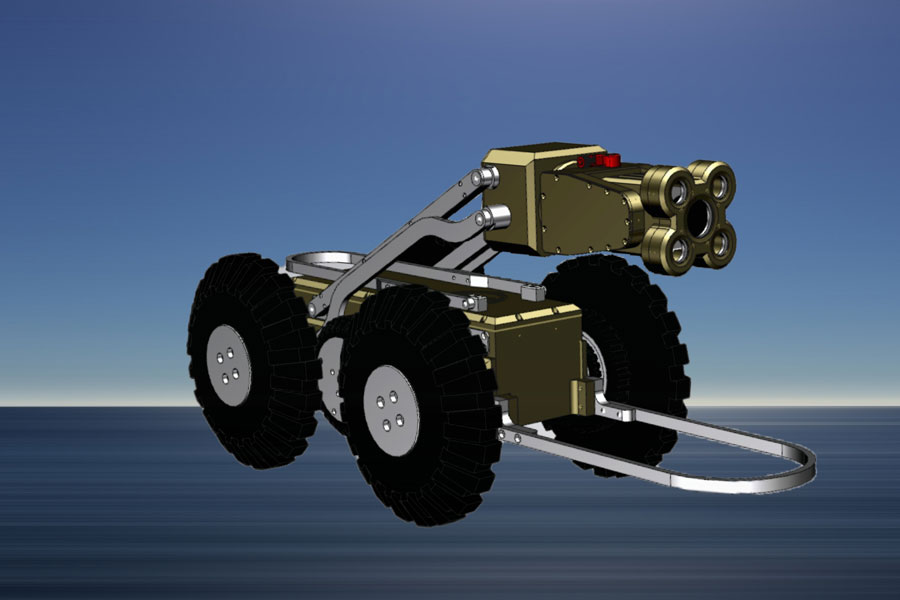

- (2) Roller mobile type, using a roller-driven walking structure, with a motor as the prime mover, in order to increase traction, generally adopts multi-wheel drive, because the wheel diameter is too small, the ability to overcome obstacles is limited, and the structure is complicated.

- (3) Crawler mobile type, imitating the walking principle of crawler vehicles, driven by DC servo motor with gear reducer.

- (4) The foot-and-leg mobile type. The basic principle is to use the feet and legs to press the tube wall to support the body, and the multi-legs can easily move in various shapes of bends. It is composed of foot support mechanism, traction mechanism and steering mechanism, which can move in various types of pipelines.

- (5) Peristaltic mobile type, imitating the creeping forward and backward motion design of insects when crawling on the ground, the mechanism is composed of peristaltic screw, nut, front and rear supporting feet and front and rear closed springs. When walking, the upper ends of the left and right supporting feet are in contact with the pipe wall, and the lower ends are in contact with the pipe wall with a roller. The peristaltic screw is driven to turn left and right in turn, so that the nut moves left and right on the screw.

- (6) Spiral moving type, using the screw principle to make the motor outside the tube push the elastic driving part forward, and the driving screw part can automatically cross the small steps.

Link to this article:The Types Of Pipeline Robots

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:The Types Of Pipeline Robots

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^