Deprecated: get_settings is deprecated since version 2.1.0! Use get_option() instead. in /www/sites/alloy.wiki/index/wp-includes/functions.php on line 4862

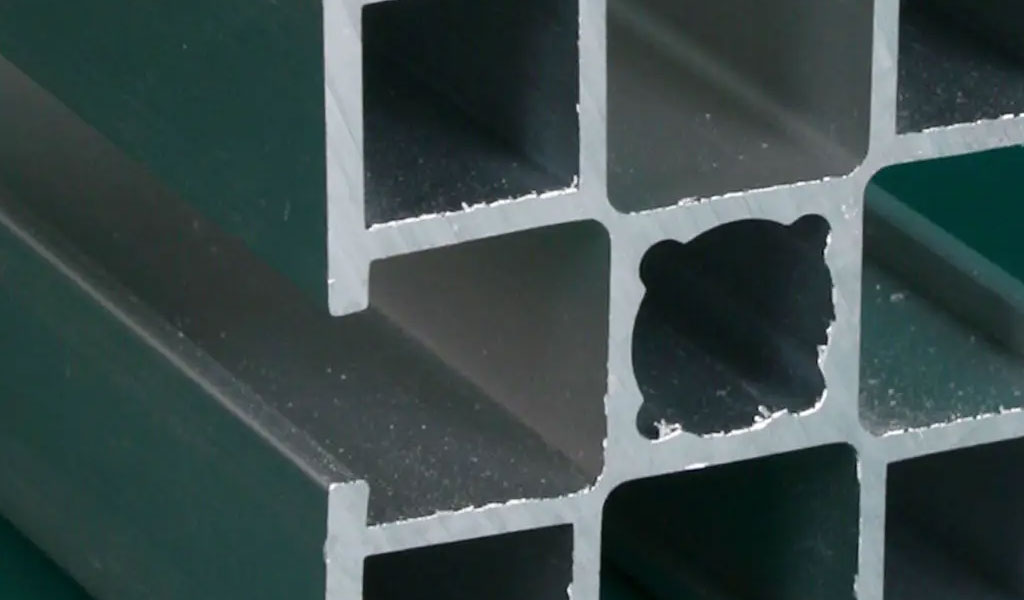

6063 aluminum alloy profile is a heat-treatable and strengthened aluminum material made of aluminum as the main raw material and alloy elements such as silicon, magnesium, and manganese. It is mainly used for architectural alloy profiles and industrial aluminum profiles . Its alloy composition and dimensional tolerance and other parameters must comply with the national standard GB/T5237.1-2008. Aluminum profiles of different materials are composed of different chemical compositions, and their tensile strength, yield strength, hardness and other properties are different. The following is a systematic introduction to the various industrial parameters of 6063 aluminum alloy profiles.

| Table 1: Chemical content of alloying elements | ||||||||||

| Alloy grade | Silicon | Iron | Cu | Magnesium | Chromium Cr | Manganese Mn | Zinc | Steel | Other elements | Al |

| 6063 | 0.2-0.6 | ≤0.35 | ≤0.1 | ≤0.49-0.9 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | Single ≤ 0.05 All ≤ 0.15 | margin |

The aluminum profiles after extrusion shall be marked with alloy grade, chemical composition, product specifications, supply status and implementation standards. The implementation standards of aluminum extrusion profiles are divided into GB/T5237-2008 for architectural profiles and GB/T6892-2006 for industrial aluminum profiles. Generally speaking, the implementation standards of GB/T5237-2008 are more stringent. The chemical composition of 6063 series aluminum profiles mainly includes aluminum, magnesium, silicon, manganese, zinc, titanium, chromium, iron, copper and other small amounts of alloy elements. The specific content is shown in the figure above. The fixed length is 6000mm/root. Its main parameters can be expressed as: 6063-T5 421001×6000 GB/T5237-2008. If a product with unqualified chemical composition is found, the entire batch of aluminum profile products will be regarded as unqualified products and cannot be put into the market for use.

| Table 2: Implementation standard GB/T5237-2008 | |||||||||

| Alloy grade | Supply Status | Wall thickness/mm | Tensile strength (MPa) | Specified non-proportional tensile strength (MPa) | Elongation after fracture/% | Sample thickness mm | Vickers hardness HV | Webster hardness HW | |

| A | A 50mm | ||||||||

|

6063

|

T5 | all | 160 | 110 | 8 | 8 | 0.8 | 58 | 8 |

| T6 | all | 205 | 180 | 8 | 8 | ||||

The supply state of 6063 aluminum alloy profiles is mainly T5, and some are in T6 state. Both T5 and T6 are heat treatment states. T5 means that the extruded aluminum profile is cooled at high temperature and then artificially aged. It is no longer cold processed, but can be straightened. Air cooling is usually used to slowly reduce the temperature of the aluminum profile to achieve its hardness and stabilize its physical properties. This method is called natural cooling. The material deformation coefficient is small and the mechanical properties are not affected. The T6 state refers to the aluminum profile being formed at high temperature and then placed in water to cool it rapidly to increase the plasticity and toughness of the material. It is also called artificial aging. 6063 alloy aluminum profiles are usually in T5 state, with higher tensile strength and hardness, and more stable mechanical properties.

| Table 3: Wall thickness tolerance range (unit: mm) | |||||||

| level | Nominal wall thickness mm | Permissible deviation of profile wall thickness corresponding to the following circumscribed circle diameters/mm (a, b, c, d) | |||||

| ≤100 | >100∽250 | >250∽300 | |||||

| A | B、C | A | B、C | A | B、C | ||

| advanced | ≤1.50 | 0.13 | 0.21 | 0.15 | 0.23 | 0.30 | 0.35 |

| >1.50~3.00 | 0.13 | 0.21 | 0.15 | 0.25 | 0.36 | 0.38 | |

| >3.00~6.00 | 0.15 | 0.25 | 0.18 | 0.30 | 0.38 | 0.45 | |

| >6.00~10.00 | 0.17 | 0.51 | 0.20 | 0.60 | 0.41 | 0.90 | |

| >10.00~15.00 | 0.17 | — | 0.20 | — | 0.41 | — | |

| >15.00~20.00 | 0.20 | — | 0.23 | — | 0.43 | — | |

| >20.00~30.00 | 0.21 | — | 0.25 | — | 0.46 | — | |

| >30.00~40.00 | 0.26 | — | 0.30 | — | 0.48 | — | |

| Ultra-high precision | ≤1.50 | 0.09 | 0.10 | 0.10 | 0.12 | 0.15 | 0.25 |

| >1.50~3.00 | 0.09 | 0.13 | 0.10 | 0.15 | 0.15 | 0.25 | |

| >3.00~6.00 | 0.10 | 0.21 | 0.12 | 0.25 | 0.18 | 0.35 | |

| >6.00~10.00 | 0.11 | 0.34 | 0.13 | 0.40 | 0.20 | 0.70 | |

| >10.00~15.00 | 0.12 | — | 0.14 | — | 0.22 | — | |

| >15.00~20.00 | 0.13 | — | 0.15 | — | 0.23 | — | |

| >20.00~30.00 | 0.15 | — | 0.17 | — | 0.25 | — | |

| >30.00~40.00 | 0.17 | — | 0.20 | — | 0.30 | — | |

A qualified aluminum profile product has very strict requirements on the range of dimensional tolerance. The dimensional tolerance range is divided into high-precision and ultra-high-precision grades. There are certain differences in the parameters of the two. As shown in the figure above, the higher the grade, the smaller the error allowed, and the higher the dimensional accuracy of the product. The dimensional tolerance range of the 6063 series aluminum profiles is generally high-precision, which can be measured with high-precision calipers and special instruments. If an aluminum profile with unqualified dimensional tolerance is detected, the entire batch of materials will be regarded as unqualified products, which can be tested one by one. Qualified products can be picked out separately and used as qualified products.

| Table 4: Allowable plane clearance (unit: mm) | |||

| Nominal width of profile (W) | Plane clearance, no greater than | ||

| ≤25 | 0.20 | 0.15 | 0.10 |

| >25∽100 | 0.80%×W | 0.80%×W | 0.80%×W |

| >100∽350 | 0.80%×W | 0.80%×W | 0.80%×W |

| Any 25mm width | 0.20 | 0.15 | 0.10 |

| Table 5: Allowable bending (unit: mm) | |||||||

| Diameter of the circle | Minimum wall thickness | Curvature, not more than | |||||

| General | High precision | Ultra-high precision | |||||

| Any length of 300mm | Total length L mh | Any length of 300mm | Total length L mh | Any length of 300mm | Total length L mh | ||

| ≤38 | ≤2.4 | 1.5 | 4×L | 1.3 | 3×L | 0.3 | 0.6×L |

| >2.4 | 0.5 | 2×L | 0.3 | 1×L | 0.3 | 0.6×L | |

| >38 | — | 0.5 | 1.5×L | 0.3 | 0.8×L | 0.3 | 0.5×L |

The allowable curvature of aluminum profiles is also a parameter to measure the dimensional accuracy of the material. The allowable curvature should meet the values in Table 5. If there is no special explanation, the allowable curvature of 6063-T5 profiles should be implemented according to the high-precision standard, and other profiles can be implemented according to the ordinary standard.

The curvature measurement method: Place the material on a horizontal surface, wait for the profile to stabilize naturally, and measure the maximum gap between the material and the table along the length direction of the material. This value represents the curvature value of the aluminum profile within a certain length.

| Table 6: Allowable depth of profile surface defects (unit: mm) | ||

| state | Defect allowable depth | |

| Decorative surface | Non decorative surface | |

| T5 | ≤0.03 | ≤0.07 |

| T6 | ≤0.06 | ≤0.10 |

During the production and transportation of aluminum profiles, collisions and frictions are unavoidable. As long as there are no obvious cracks and bubbles and the depth of surface defects is within the allowable range, as shown in the figure above, it is acceptable. Within this specified range, aluminum profiles with clean surfaces and no serious defects such as orange peel and pitting corrosion are qualified products. Products with poor appearance are considered unqualified products and cannot be put into use. They must be strictly selected during inspection to prevent inferior products from entering the market, affecting the performance of aluminum profiles, and even causing safety hazards.

| Table 7: Allowable depth of die extrusion mark (unit: mm) | |

| Alloy grade | Die extrusion mark depth |

| 6063 | ≤0.03 |

The use of molds during extrusion of aluminum profiles is also critical. When removing the mold, a certain degree of indentation may be caused on the surface of the profile. As long as this value is below 0.03mm, it is a qualified product. The materials must be checked and measured one by one. If it exceeds this value, it will cause a large deviation in the size of the aluminum profile , resulting in poor appearance or poor mechanical properties. The quality of the mold must be checked and repaired in time. If there are only slight indentations, later repair measures can be taken. If there are obvious deep indentations, this batch of aluminum profile products must be scrapped.

Link to this article:6063 Aluminum Alloy Profile National Production Standard

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^