1. Multi Processor control system SIMATIC TDC

SIMATIC TDC solves even complex drive, control and technology tasks with maximum quantity frameworks and shortest cycle times on one single platform. The system is used particularly for large plants in the process, energy and drive technology.

Metal production and metal processing: Wire-drawing plants, stretcher levelers, bending and straightening machines, presses, circular arc type plants, rolling mills, upsetting devices, shearing and winding machines and High Voltage Direct Current Transmission Systems (HVDC).The last one is Flexible AC Transmission Systems (FACTS), e.g. Reactive Power Compensation solutions.

Features

Performance

The powerful processor modules of SIMATIC TDC allow the processing of maximum quantity frameworks in short cycle times down to 100 µs.

Scalability

Tailored hardware configurations: From mounting a suitable number of processor modules for synchronous processor operation to the synchronous coupling of whole racks – with SIMATIC TDC the automation system can be scaled modularly over a wide range.

Flexibility

The engineering of even complex control structures is carried out efficiently with the SIMATIC standard languages CFC and SFC and an extensive function block library. The user gets a maximum flexibility by creating own user libraries based on ANSI C code.

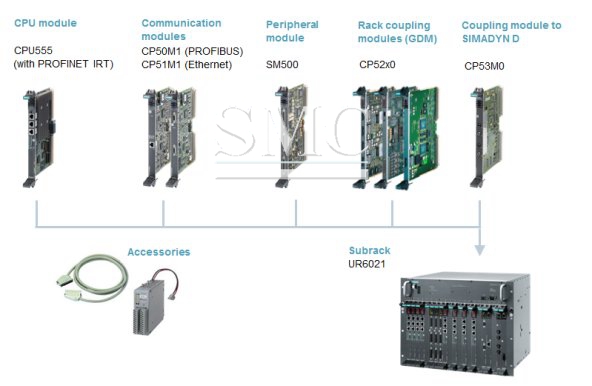

Modular system design

SIMATIC TDC is a modular multi-processor system which consists of one or several subracks. The subracks (VMEbus standard) are equipped with processor, periphery and communication modules. For the connection to further automation components SIMATIC TDC supports the communication standards are PROFINET/ PROFIBUS / Industrial Ethernet.

2. High-End Application Module FM 458-1 DP

Within the SIMATIC S7-400, the enhanced application module FM 458-1 DP is setting new standards. This intelligent module combines powerful arithmetic operations ability, high processing speed, precision and flexibility. These are the features required to solve a wide range of processing tasks universally even with extremely high throughput rates.

Communication

Communication takes place over the PROFIBUS DP interface on the FM 458-1 DP.

This offers the following characteristics such as constant bus cycle time, i.e. the PROFIBUS DP cycle is always precisely the same length.Then goes isochronous, i.e. the CPU, I/O and user program which are synchronized with the PROFIBUS cycle.Two others are slave-to-slave communication, i.e. the configured slaves can exchange data with each other directly without the need for any additional configuring work on the FM 458-1 DP and routing capability, i.e. all nodes are accessed over one interface, e.g. MPI (Multi-Point Interface) or PROFIBUS DP and optionally also Industrial Ethernet.

Advantages

In the list of advantages are integrated into SIMATIC S7-400 racks: Open-loop and closed-loop control and arithmetic operations.What is more, software tools STEP 7/CFC and SFC are identical to the tools for SIMATIC S7.ANother two advatnages are sampling times from 100 µs for dynamic motion control and processing solutions. Isochronous PROFIBUS DP and clock synchronism (CPUs/I/O and user programs are synchronized to common PROFIBUS clock) are also one of the benefits.The last one is routing, diagnostics and teleservice possible do via a single interface

The I/O expansion EXM 438-1 provides extremely fast, synchronizable Digital and analog inputs and outputs and Speed and absolute value encoder measurement.

The EXM 448/EXM 448-1 communication expansions provide fast connection of drives including PROFIBUS DP, as master or slave (not isochronous/clock-synchronized)and SIMOLINK, the fast, powerful, clock-synchronized fiber-optic cable (installed in EXM 448-1).

Task

Counting/Measuring

Suitable for a wide range of different counting and measuring tasks with incremental or absolute value encoders up to a maximum of 2.5 MHz.

Cam Controls

16 digital outputs as cam tracks (displacement or time cams). Each track can be individually adapted to the task with a delay or overrun. Dynamic delay, dynamic hysteresis.

Closed-loop Control

Controller structures/types are freely programmable, e.g. fixed value control, follow-on control, cascading control, ratio and mixer controls, continuous and override control, pressure, level and temperature control, hydraulic control, drive control.

Motion Control

Open/closed-loop controlled positioning of up to 16 individual axes as well as multi-axis applications over PROFIBUS DP or SIMOLINK.

Shanghai Metal Corporation is a trusted aluminum alloy, aluminum foil price, stainless steel price and stainless steel manufacturer, kinds of stainless steel in china.

Guest contributors are welcome at the Alloy Wiki.It is a weekly wiki and guide on alloy information and processing technology, while also about the vast array of opportunities that are present in manufacturing. Our team of writers consists of a Machining Material Supplier / Machinist / Tool and Die Maker, a Biomedical Engineer / Product Development Engineer, a Job Development Coordinator / Adjunct Professor, and a President and CEO of a manufacturing facility.

Link to this article:Siemens control systems

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^