Every night, every family will turn on the lights. I believe that everyone should be familiar with the incandescent lamps commonly used in the home. From the beginning of the invention of this incandescent lamp, it has been more than 100 years old. At the same time, the invention of electric lights also brought a lot of convenience to our lives. Some curious little friends asked, how did the tungsten wire in the bulbs fit in? Let’s take a look at it below.

Everyone knows that this kind of incandescent lamp can have a certain connection with the tungsten wire inside, but the inside of the light does not have tungsten wire. It also needs to have the wick fixing and the conductive wire glass tube and other materials. First, the glass tube is subjected to high-temperature hot-melting, and then formed into a bulb shape, that is, a trumpet shape, and then the glass tube flare is directed upward, and the both sides are fixed, and then two conductive electrodes are placed on both sides of the glass tube. Wire, placed a wick in the middle of the conductive wire.

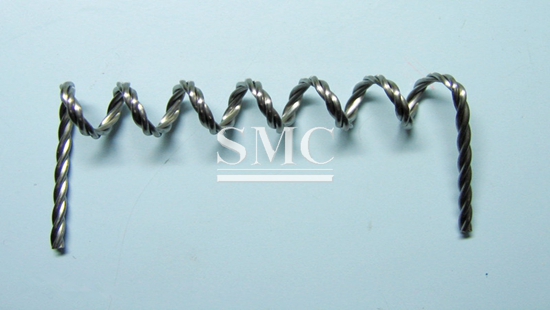

Then, the bottom of the glass tube is heated by a special heater, and when it can be softened, it is molded by a specific mold, and then heated and softened at the top of the wick, and the tungsten wire is attached to the wire. At the top of the wick, the tungsten wire should be fastened on the tungsten wire. At this time, the wick is finished, then the wick tube is fixed, the glass case is buckled, and then the bottom and inside of the glass case are passed through the heater. The filament glass tube is combined.

Then, using the vacuum pumping device, the air inside is evacuated, an inert gas is injected, and the excess wick portion is melted at a high temperature by the machine.

The last is to combine the lamp holder with the bulb and finally seal the mouth, so that a bulb is completed. I don’t expect the bulb to be very simple and straightforward from the outside, but it is so complicated to make.

Guest contributors are welcome at the Alloy Wiki.It is a weekly wiki and guide on alloy information and processing technology, while also about the vast array of opportunities that are present in manufacturing. Our team of writers consists of a Machining Material Supplier / Machinist / Tool and Die Maker, a Biomedical Engineer / Product Development Engineer, a Job Development Coordinator / Adjunct Professor, and a President and CEO of a manufacturing facility.

Link to this article:How did the Tungsten Wire Get in the Bulb?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^