Industrial Personal Computer, also known as industrial computer host, is a hardware assembly that integrates industrial motherboards, CPUs, memory, motherboards, hard drives, I/O input and output interfaces, and is more robust and stable than commercial computers in terms of production structure and performance. Simply understood as Industrial Personal Computer is a computer host for industrial applications. So what does Industrial Personal Computer do? Many novices don’t know the specific structure of Industrial Personal Computer. I will tell you how to solve the structure and composition of Industrial Personal Computer produced and processed by PTJ.

Understand the hardware composition and working principle of Industrial Personal Computer in one article

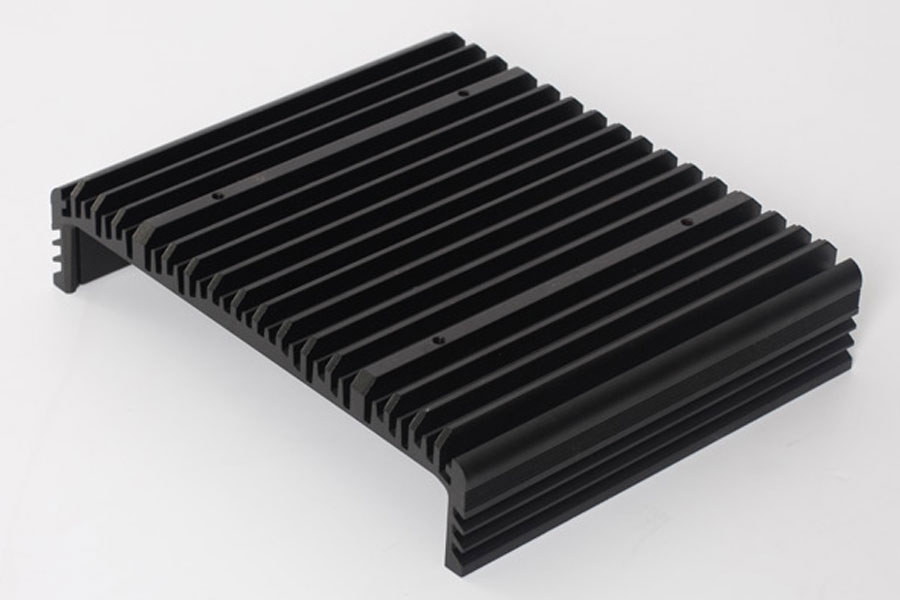

First, let’s take a look at the overall appearance of Industrial Personal Computer as shown below:

From the appearance, it is known that Industrial Personal Computer is equipped with a front baffle and a mold opening on the baffle to install I/O interfaces and power switches. The black part is made of Aluminum Alloy profiles and the fin-type design is mainly for heat dissipation to increase the heat dissipation area. need. Let’s explain the appearance of Industrial Personal Computer before assembly, as shown in the figure below:

The appearance structure of Industrial Personal Computer is front baffle, rear baffle, heat dissipation aluminum fins and stainless steel sheet on the back cover. Install COM, VGA, power switch, USB interface and other input and output parts on the front and rear baffles.

In terms of heat dissipation, the fanless Industrial Personal Computer uses aluminum profiles. The design of this aluminum profile is to increase the heat dissipation area and stabilize the performance of Industrial Personal Computer. According to what the structural engineer asked by the editor, Industrial Personal Computer is applied to this aluminum profile. First, the aluminum alloy is formed by pouring and extruding the half-melting aluminum alloy when the aluminum alloy is in the state of the half melting point. The concave-convex strip housing.

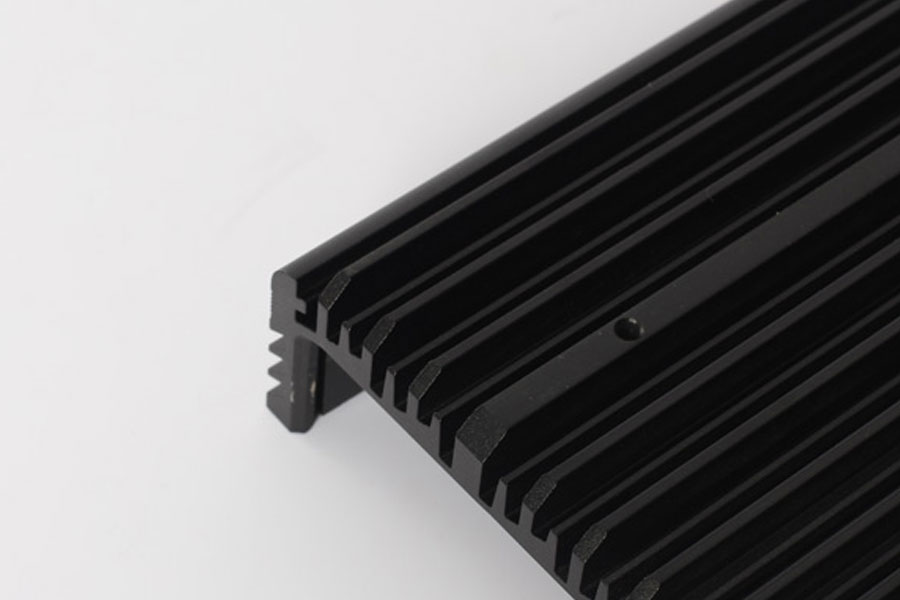

After the back shell is extruded, a hole is punched on the back through a machining process, which is convenient for customers to install Industrial Personal Computer.

When making the fins, the structural engineers have considered the product assembly issues. When assembling, the back of Industrial Personal Computer’s radiating fins is machined with holes and slots to facilitate the assembly of front and rear baffles and the installation of the motherboard.

From the above picture, we know that the machining is for the front and rear baffles, and the design is seamless. This structure design is dustproof and durable.

When installing Industrial Personal Computer, the factory usually installs the cable design and the case, installs the CPU, memory, hard disk, heat sink, etc. on the motherboard, and then puts this into the junction box for wiring.

The editor remembers that once I saw the boss screwing in the factory, the editor asked curiously, “Boss, why did you come to the assembly department to screw screws?”. The boss replied weakly: “Don’t you think that screwing is a very happy thing?” Afterwards, the editor understood what the boss was in at the time. The other screwing was the last step. A complete Industrial Personal Computer will be born. I am in a good mood to see the “work” after screwing.

Link to this article : Industrial Personal Computer Case Production Structure

Sheet metal, Copper Milling, carbon steel,online laser cutting service, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Sheet metal, Copper Milling, carbon steel,online laser cutting service, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:Industrial Personal Computer Case Production Structure

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^