Notice: Undefined index: sith_hide_share in /www/sites/alloy.wiki/index/wp-content/themes/likegoogle/single.php on line 32

Deprecated: get_settings is deprecated since version 2.1.0! Use get_option() instead. in /www/sites/alloy.wiki/index/wp-includes/functions.php on line 4862

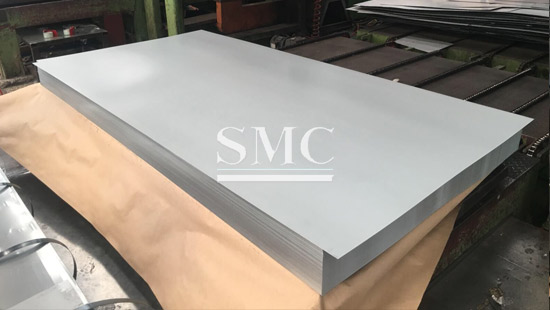

Electrogalvanized steel coil refers to the roll-shaped galvanized sheet adopting electrolytic galvanizing process. Galvanized steel coil, a steel material coated with zinc on its surface. The galvanized coil is the predecessor of the galvanized sheet. The equipment is used to cut the galvanized coil into a sheet. The galvanized coil is placed on the shelf with a forklift or a crane and then transported, flattened and sheared by the equipment. The width is standard width one meter, one meter two or five, one meter five or three, and the length is arbitrary.

The use of electrogalvanized steel coil: The coated steel plate has light weight, beautiful appearance and good anti-corrosion performance, and can be directly processed. It provides a new type of raw material for the construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry, electrical industry, etc. Wood, efficient construction, energy saving, pollution prevention and other good effects.

In addition to zinc protection, the color-coated steel plate using galvanized steel plate as the substrate, the organic coating on the zinc layer plays a role of covering isolation, which can prevent the steel plate from rusting, and the service life is longer than the galvanized steel plate. According to the introduction coating The service life of steel plate is 50% longer than galvanized steel plate. However, in different regions and different application parts, the service life of color-coated boards with the same galvanizing amount, the same paint and the same coating thickness will be very different. For example, in industrial areas or coastal areas, due to the effects of sulfur dioxide gas or salt in the air, the corrosion rate is accelerated and the service life is affected. In the rainy season, the coating will be wetted by rain for a long time, or the part where the temperature difference between day and night is too large and easy to condense will be corroded quickly, and the service life will be reduced.

Buildings or workshops made of colored coated steel plates often have a long service life when they are washed by rain. Otherwise, they will be affected by the use of sulfur dioxide gas, salt, and dust. Therefore, when designing, the greater the inclination of the roof, the less likely to accumulate dust and other dirt, and the longer the service life; those areas or parts that are not frequently washed by rain should be washed regularly with water.

Guest contributors are welcome at the Alloy Wiki.It is a weekly wiki and guide on alloy information and processing technology, while also about the vast array of opportunities that are present in manufacturing. Our team of writers consists of a Machining Material Supplier / Machinist / Tool and Die Maker, a Biomedical Engineer / Product Development Engineer, a Job Development Coordinator / Adjunct Professor, and a President and CEO of a manufacturing facility.

Link to this article:The Use of Electrogalvanized Steel Coil

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^