Every year hundreds of thousands of people seek out dental treatment for a variety of reasons. Often times the main issue with the dental industry is the cost and time it takes for certain procedures to be complete. If a patient is in need of a new bridge, crown, or false tooth it can often take weeks or even months for the item to be molded, shaped, and shipped to the local dental practitioner. One company, however, is looking to change that. Last month, Telpro Management launched electronics manufacturer Roland’s DWX-52DC. This machine is designed to manufacture crowns and bridges in an hour’s time. But how does it work and what kind of effect will this have on the dental industry?

The Traditional Method

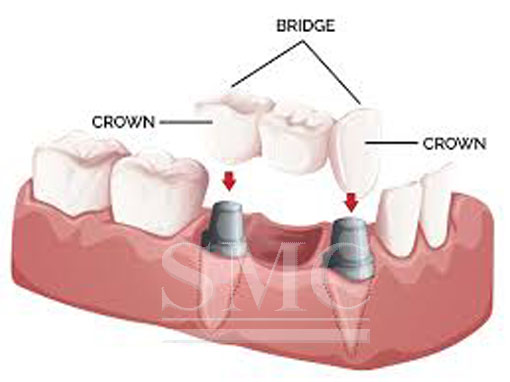

The traditional bridge, crown, and false tooth manufacturing process takes a minimum of six weeks and is very labor intensive. First, a dental practitioner will take an impression of the affected tooth, design a replacement crown or bridge, and send it to a lab for it to be sintered for 16 hours and then the tooth will be sent back. The material used in this traditional method is zirconia. Zirconia is used because it can be machined and baked to achieve the same hardness as a regular tooth. However, the long production and wait time makes it not only inconvenient but also costly.

The DWX-52DC

This fully automatic device uses intra oral scanning techology that eliminates the need for traditional casting practices. It also allows the new teeth replacements to be designed on screen using the Exocad software. The machine has a library that contains discs used to make the teeth and allows the user to know which part of the discs have been used. This saves both space in the machine and money. The teeth are produced by two materials. Zirconia, the traditional material, along with the PEEK, a high-performance engineering plastic, is easy to work with and used as a material to make dental plates. This device reduces the cost of artificial tooth production by 70%. A new tooth can be manufactured from start to finish in around an hour’s time. Minimizing the time spent in a patient’s mouth, the cost of a new tooth, and the energy required to make the tooth. The DWX-52DC’s innovative technology is taking the dental industry by storm, saving time, money, and energy of dentists and patients alike.

Guest contributors are welcome at the Alloy Wiki.It is a weekly wiki and guide on alloy information and processing technology, while also about the vast array of opportunities that are present in manufacturing. Our team of writers consists of a Machining Material Supplier / Machinist / Tool and Die Maker, a Biomedical Engineer / Product Development Engineer, a Job Development Coordinator / Adjunct Professor, and a President and CEO of a manufacturing facility.

Link to this article:New Smiles in No Time

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^