Deprecated: get_settings is deprecated since version 2.1.0! Use get_option() instead. in /www/sites/alloy.wiki/index/wp-includes/functions.php on line 4862

Laser micromachining technology has the advantages of non-contact, wide range of processing materials, high precision, high repetition rate, small heat-affected zone, and high flexibility in shape and size processing. It is widely used in micromachines, microelectronic devices, medical equipment, aviation precision manufacturing, etc. field. At present, most studies on ultrashort pulse laser micro manufacturing use low-power lasers (P<30W). Compared with low-power lasers, high-power ultrashort pulse lasers have higher processing capabilities, but there are currently few studies on high-power ultrashort pulse laser material removal processing, especially laser powers higher than 100W.

The laser and intelligent energy field manufacturing engineering team led by Zhang Wenwu of the Institute of Advanced Manufacturing of Ningbo Institute of Materials, Chinese Academy of Sciences, based on the independently developed open five-axis linkage CNC system and combined it with a two-axis scanning galvanometer, developed a five-axis linkage 300W picosecond Laser processing and 40W nanosecond laser processing system. Using a 300W picosecond laser cutting system, the team processed micro-grooves on copper, aluminum, quartz and other materials, and analyzed the impact of different processing parameters on the width and depth of micro-grooves. This achievement was jointly completed by Jiao Junke, Ruan Liang, Zhang Tianrun, and Zhang Wenwu. It was reported as a keynote report on the energy field manufacturing forum at the ASME 2014 Manufacturing Science and Engineering Conference in Detroit, USA, and aroused widespread interest among participating scholars.

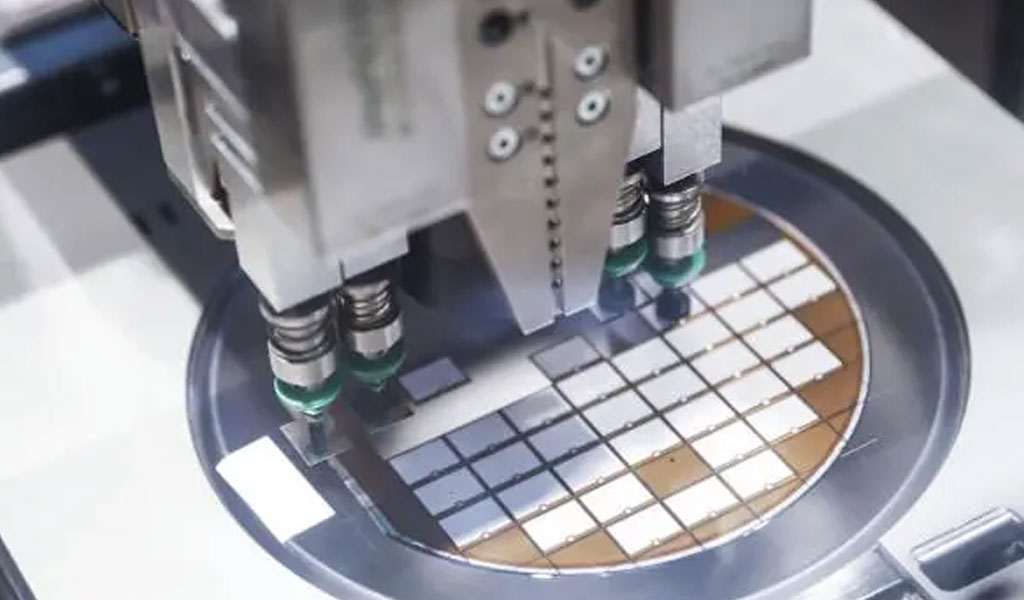

This research promotes the development and application of high-speed micro-nano processing technology. Because the speed of micro-machining is increased by 5-10 times compared to conventional systems, and thermal effects are well controlled, combined with the independently developed five-axis platform and software interface, it lays the foundation for laser precision processing of large-scale complex shapes. When the experimental conditions are 2-20MHz, the maximum laser power is 300W, the wavelength is 1064nm, and the frequency adjustment range is 400KHz-20MHz. The laser beam is reflected into the scanning galvanometer, and the focused spot is about 40-75um. The micromachining path is controlled by a scanning galvanometer with a maximum speed of 10m/s. Research shows that high-power femtosecond laser cutting is an effective tool for micromachining. Different scanning layers, laser powers, and scanning speeds have different material removal efficiencies. The study compared the processing efficiency of nanosecond laser and picosecond laser, and found that the processing efficiency of picosecond laser is higher than that of nanosecond laser. As shown in the figure, the material removal rate per unit energy of picosecond laser is compared within a certain depth range. More than twice that of a nanosecond laser. The team used confocal microscopy to accurately measure the microgroove processing results (Figure 3). The measurement accuracy is less than 140 nanometers in the XY direction and less than 10 nanometers in the Z direction. The roughness of the groove, the machined three-dimensional shape and the removal volume are measured with high reliability.

The paper further reveals the impact of laser pulse energy, average power, etc. on the material removal rate, and points out that single pulse energy is closely related to the depth of processing capabilities. The depth capability of ultrashort pulse lasers is suitable for micro-machining less than 3 mm, and high-efficiency large-depth micro machining requires further process breakthroughs. The team’s next step will be to explore water-assisted laser processing to further improve the processing depth capabilities of pulse lasers.

Link to this article:Ningbo Material Institute Has Made Progress In Pulsed Laser High-Speed Micromachining

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^