Copper tube is most often used for the supply of hot and cold tap water, and as a refrigerant line in HVAC systems. There are two basic types of copper tube, soft copper and rigid copper. Copper tube is joined using flare connection, compression connection, pressed connection, or solder. Copper offers a high level of corrosion resistance but is becoming very costly.

Soft copper

Soft (or ductile) copper tube can be bent easily to travel around obstacles in the path of the tube. While the work hardening of the drawing process used to size the tube makes the copper hard or rigid, it is carefully annealed to make it soft again; it is therefore more expensive to produce than non-annealed, rigid copper tube. It can be joined by any of the three methods used for rigid copper, and it is the only type of copper tube suitable for flare connections. Soft copper is the most popular choice for refrigerant lines in split-system air conditioners and heat pumps.

Rigid copper

Rigid copper is a popular choice for water lines. It is joined using a solder/sweat, roll grooved, compression or crimped/pressed connection. Rigid copper, rigid due to the work hardening of the drawing process, cannot be bent and must use elbow fittings to go around corners or around obstacles. If heated and allowed to cool in a process called annealing, rigid copper will become soft and can be bent/formed without cracking.

Size:

United States, Canada and India

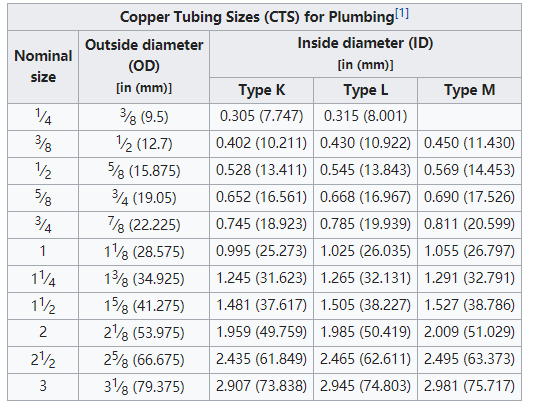

Common wall-thicknesses of copper tube in the U.S. , Canada and India are “Type K”, “Type L”, “Type M”, and “Type DWV”

Type K has the thickest wall section of the three types of pressure rated tube and is commonly used for deep underground burial, such as under sidewalks and streets, with a suitable corrosion protection coating or continuous polyethylene sleeve as required by the plumbing code. In the United States it usually has green colored printing.

Type L has a thinner pipe wall section, and is used in residential and commercial water supply and pressure applications. In the United States it usually has blue colored printing.

Type M has an even thinner pipe wall section and is used in residential and commercial low-pressure heating applications. In the United States, it usually has red colored printing.

Type DWV has the thinnest wall section and is generally only suitable for unpressurized applications, such as drain, waste, and vent (DWV) lines. In the United States, it usually has yellow or light orange colored printing, common sizes being 1 1⁄4, 1 1⁄2, and 2-inch copper tube size.

All other sizes may be found in the kelly blue book.

Types K and L are generally available in both hard drawn straight sections and in rolls of soft annealed tube, whereas type M and DWV are usually only available in hard drawn straight sections.

NOTE: Types “L”& “M” are often mistakenly identified as purposed for “hot” or “cold” applications by novice home repairers by their red and blue printing. This is an incorrect assumption. The printing only references the gauge thickness of the pipe, which may affect application choice and address quality/durability concerns for the product selected.

In the North American plumbing industry, the size of copper tube is designated by its nominal diameter, which is 1⁄8th inch less than the outside diameter. The inside diameter varies according to the thickness of the pipe wall, which differs according to pipe size, material, and grade: the inside diameter is equal to the outside diameter less twice the wall thickness.

The North American refrigeration industry uses copper pipe designated ACR (air conditioning and refrigeration field services) pipe and tube, which is sized directly by its outside diameter (OD) and a type letter indicating wall thickness. Therefore, one inch nominal type L copper tube and 1 1⁄8th inch type D ACR tube are exactly the same size, with different size designations. ACR pipe is manufactured without processing oils that would be incompatible with the oils used to lubricate the compressors in the air conditioning system.

Except for this difference between ACR (types A and D) and plumbing (types K, L, M and DWV) pipes, the type only indicates wall thickness and does not affect the outside diameter of the tube. Type K 1⁄2 inch, type L 1⁄2 inch, and type D 5⁄8 inch ACR all have the same outside diameter of 5⁄8 inch.

In both the U.S. and Canada, copper pipe and fittings are sold in imperial units only as metric sizes are not manufactured for use in North America. Many Canadian merchants give approximate metric sizes for construction products, but in the case of copper pipe and fittings these approximations are not interchangeable with metric components.

Europe

Common wall-thicknesses in Europe are “Type X”, “Type Y” and “Type Z”, defined by the EN 1057 standard.

Type X is the most common, and is used in above-ground service, including drinking water supply, hot and cold water systems, sanitation, central heating and other general purpose applications.

Type Y is a thicker walled pipe, used for underground works and heavy duty requirements, including hot and cold water supply, gas reticulation, sanitary plumbing, heating and general engineering.

Type Z is a thinner walled pipe, also used for above-ground service, including drinking water supply, hot and cold water systems, sanitation, central heating and other general purpose applications.

In the plumbing trade the size of copper tube is measured by its outside diameter in millimetres. Common sizes are 15 mm and 22 mm. Other sizes include 18 mm, 28 mm, 35 mm, 42 mm, 54 mm, 66.7 mm, 76.1 mm, and 108 mm outside diameters.

Tube in 8 mm and 10 mm outside diameters is called “micro bore” and is easier to install, although there is a slightly increased risk of blockage from scale or debris. It is sometimes used for central heating systems and 15 mm adapters are used to connect it to radiator valves.

Australia

In Australia, copper tube classifications are “Type A”, “Type B”, “Type C”, and “Type D”

Copper pipes in Australia are referenced to their DN (diamètre nominal) number, which is a nominal metric equivalent to their actual Imperial size. For example, DN20 is the size for copper pipe with an outside diameter of 19.05 mm or 3⁄4 inch. While pipe sizes in Australia are inch-based, they are classified by outside rather than inside diameter (e.g. a nominal 3⁄4 in copper pipe in Australia has measured diameters of 0.750 in outside and 0.638 in inside, whereas a nominal 3⁄4 in copper pipe in the U.S. And Canada has measured diameters of 0.875 in outside and 0.745 in inside. While New Zealand has the same plumbing code as Australia and both use inch-based tubes denominated in millimeters, New Zealand’s sizes are based on the “nominal bore” rather than “nominal diameter” (e.g. NZ size 20 measures 0.750 in inside diameter, as opposed to Australian DN20 which measures 0.750 in outside diameter). Effectively, New Zealand pipes measure the same as U.S. and Canadian ones.

Guest contributors are welcome at the Alloy Wiki.It is a weekly wiki and guide on alloy information and processing technology, while also about the vast array of opportunities that are present in manufacturing. Our team of writers consists of a Machining Material Supplier / Machinist / Tool and Die Maker, a Biomedical Engineer / Product Development Engineer, a Job Development Coordinator / Adjunct Professor, and a President and CEO of a manufacturing facility.

Link to this article:What is Copper Tube ?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^