About 15 years ago, a survey was conducted on people who bought pressure brakes and found that only about 10% of them actually used the new brake software they bought. People’s reactions indicate that the manufacturer believes that the software is only useful for complex parts. Ordinary parts can be easily programmed in the press brake, because it does not require so much time.

Now, metal manufacturers see the light. Almost all new stamping brake owners not only buy software for their new bending machines, but also plan to use as many programming tools as possible.

As production speeds increased and faced with shorter delivery times, metal manufacturers saw the importance of software in ensuring that their brakes were used to form parts.

Bending software is the key to persuading metal manufacturers that they can move parts and actually increase the normal time of press brakes.

If the shop is to minimize non-value-added activities related to bending and ensure that the bending machine makes parts as efficiently as possible, management needs to be aware of how bending software can achieve this goal.

1. Make the most of talented operators

Every manager in the metal processing business knows that it is very difficult to find someone capable of working on a bending machine, let alone someone who actually works on a bending machine. There are few operators who can see how 3D objects are formed, know what combination of punch and die to achieve their goals, and sort tools in the most effective way. If you do not use bending software, you can recommend the appropriate tools and automatically create a bending sequence for a typical part, then it takes about 15 to 30 minutes for the bending machine expert to set up the bending machine.

Imagine how long it takes for a novice, about 30 to 60 minutes. The magnets on the bending machine will support a blueprint. The operator will stare at it, trying to figure out the correct combination of punch and die to be used and the bending sequence to be proposed. In this case, the bending machine will not move up and down.

This is why the shop needs their best bending machine operators to program parts offline. Now this sounds incredible, especially after discussing the speed at which these people can actually produce parts. But our goal is to make all press brake operators work as efficiently as possible, not just experienced operators.

The bending software will handle simple parts such as hat grooves. Experienced bending machine veterans can pay attention to things such as manufacturability and schedule design, but the software will do most of the work on these parts.

For complex work of 10% to 20%, at least 6 bends are required. In fact, the veteran will find the best way to bend this part. The most savvy metal forming mind will not spend time on the monotonous work of simple part programming. Even considering the possibility that new tools may be needed, he can review his experience to determine the appropriate way to form the part. The bending machine software keeps these in mind, so the software can be developed to manually edit the suggested bending machine operation.

After the part program is completed, the programmer can save it to the database so that it can be shared with the bending department. Now, less experienced operators will get the best guidance. They call up the program, make sure they have the correct tools in the machine, and follow the prompts on the controller screen.

Directly link bending productivity to a specific press brake operator. Even if the most savvy operators take sick leave that day, now less experienced personnel can step up their operations and follow the procedures created by metal forming experts. Knowledge can be shared with everyone.

2. Create a bending program that leads to consistent production

If a store does not rely on bending software and offline programming, then it really knows how long the bending work will take? If it has a team of experienced brake operators, maybe it can, but this is not the norm in the industry.

If someone in a shop tries to figure out how to bend a part, then that person will need some time to fix it. If the same person still has some memory of the way it was done last time, then he may complete the same bending work faster. If different operators have to bend over for the same job, the department head will see completely different production times. Due to inefficiency in production, work-in-progress work in a specific department can make things even more stressful.

Offline programming of the bending program can eliminate many uncertain factors. The job has been created and saved, so operators of any skill level can call it and start working. Experienced brake operators may complete the work faster, but even less experienced people have a clearer plan to proceed.

3. Choose the right tool

In determining the tools needed for the bending machine, finding and installing them in the correct order, the operator was once the main decision maker in the installation process of the bending machine. This is a big responsibility, and it does emphasize the importance of these knowledgeable operators in stores without advanced software and automation equipment.

The bending software helps reduce the responsibility of the operator of the bending machine. The software refers to the current tool list, which has all the company’s punches, dies, and special tools, and the software determines the best tool for the job. Then save the tool settings to prevent future work.

Some bending software packages can also recommend general tool settings for processing various parts of different thicknesses and radii. The software ensures that the right tools are provided for various tasks, and the tools have a common closed height, which means that various stamping contours and V-shaped dies can be used at the same time, including crimping dies.

The software package can also access the master tool list-tools made by the same manufacturer of the bending machine. In a virtual environment, programmers using bending software can grab tools that may not be in the current list and see how they work at work. If you need a new tool, you can order it at this time and include the cost in the cost of the part.

4. Check the design intent

Many discussions have focused on inexperienced press brake operators, but engineers without experience in sheet metal processing can also cause problems, albeit unintentionally. For example, engineers are always looking for the easiest way to do things, which is the correct way to design in manufacturing. However, when doing so, engineers usually rely on the recommended K factor. This is a standard, right? In most cases, it is feasible, but if the operator of the bending machine must use a different size V-die to accommodate the short flange, the K factor required by the engineer may not be the best recommendation.

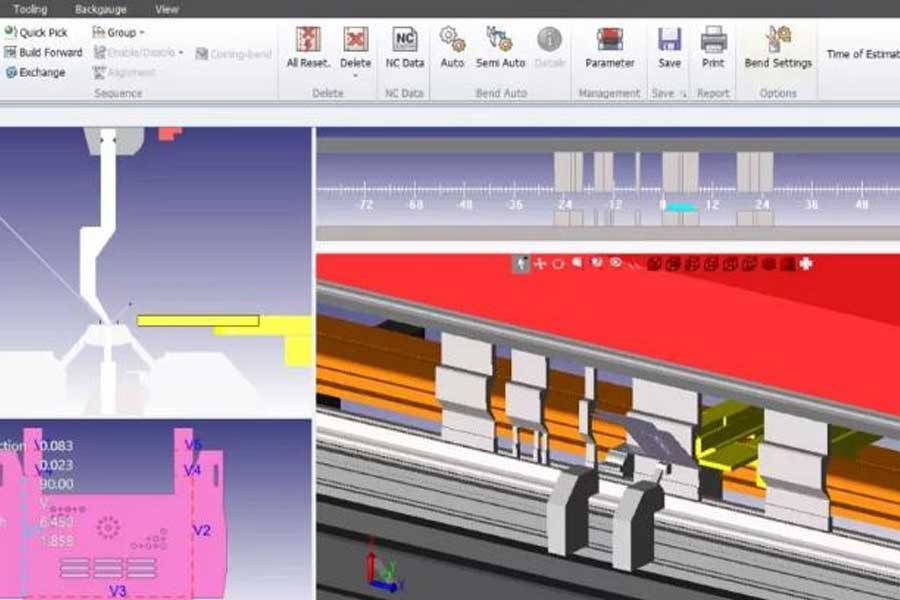

Simulation as part of modern bending software packages can help manufacturers avoid this situation. The software can analyze the 3D model of a part or assembly and determine the design intent of the manufacturing method.

From a bending point of view, the software checks whether the parts can be manufactured as specified. Will the tools collide? Is the flange too short? These manufacturing errors will never make the bending department liable.

From an overall manufacturing perspective, the same tools can be used to improve downstream production efficiency. For example, the software may suggest a new bending sequence to avoid certain downstream welding. If some manual welding is removed from the manufacturing process, such a move can reduce the cost of the part and improve the overall quality of the part. This type of computing power, combined with the skills of experienced bending machine veterans in programming seats, makes bending software a powerful tool for continuous improvement and reducing part design costs.

5. Make prototypes without monopolizing machine time

The store with the prototype unit is very unique. It takes up space that most stores don’t have, and the equipment it owns is not very dependent on production requirements. The latter is important because management does not want to devote its most productive machine to work for which no one spends money at that particular moment.

This is where software can come into play. For example, the simulation function can determine the best way to manufacture parts without having to bundle the bending machine. Likewise, no one is standing in front of the brakes, wondering which tool to use and the correct bending sequence.

Once the simulation proves the design intent and the software creates the production recipe, it can be proven in a few minutes, and it can even be combined with the production run of the day.

In addition, customers always appreciate the prompt response in the quotation. The bending simulation function of the bending software helps to achieve this goal.

Production efficiency does not stop there

The bending software is able to perform all these pre-bending activities and compress them so that the bending machine can start bending the part. But the technology has developed to such a degree, there are still many opportunities in the bending department to improve production efficiency.

Imagine if a processing plant had a machine that could automatically set up the tool in a few minutes. Now, the shop has software that can expand 3D models, select tools, create bending sequences and share it with the bending machine connected to the automatic tool center. At this point, the operator only really cares about following the work instructions and keeping the fingers safe. The most environmentally friendly people on the press brake have the opportunity to be more productive than the most experienced operator of the press brake.

It did not end there. With the help of industrial Internet of Things technology, the workshop manager can understand the actual situation of the bending department. Since the machine is connected and provides information directly to the front desk, managers no longer rely on the operator of the bending machine to log in the correct information. The machines will share the following facts: how long the setting work lasted, how long the bending work lasted, and how much time was spent at work during the shift.

Using these data, managers can ask correct questions based on actual conditions, rather than intuitive or erroneous observations. For example, you can compare similar work done by different operators, and you can compare similar work done on different shifts. Therefore, continuous improvement activities can be more targeted and have a greater impact, because these numbers indicate the biggest areas of improvement.

Of course, the optimization path of this process starts from one step. Stores need to ensure that they use the features of the bending software to the fullest extent possible.

Link to this article: How to ensure that the bending machine makes parts as efficiently as possible?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:How to ensure that the bending machine makes parts as efficiently as possible?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^