General technical requirements

- 1. Parts are descaled.

- 2. There should be no scratches, scratches, etc. on the surface of the part to damage the surface of the part.

- 3. Remove the burr flash.

Heat treatment requirements

- 1. After quenching and tempering treatment, HRC50~55.

- 2. The parts are subjected to high frequency quenching, tempered at 350 to 370 ° C, and HRC 40 to 45.

- 3. Carburizing depth is 0.3mm.

- 4. Perform high temperature aging treatment.

Tolerance requirements

- 1. Unfilled shape tolerances shall comply with the requirements of GB1184-80.

- 2. The tolerance for the length of the unfilled length is ±0.5mm.

- 3. The casting tolerance band is symmetrical to the basic size configuration of the blank casting.

Part corner

- 1. The fillet radius R5 is not marked.

- 2. The un-chamfered angle is 2×45°.

- 3. Sharp angle / sharp corner / sharp edge

Assembly requirements

- 1. Each seal must be saturated with oil before assembly.

- 2. The assembly of rolling bearings allows for hot charging with oil heating. The temperature of the oil must not exceed 100 °C.

- 3. After gear assembly, the contact spots and side gaps of the tooth surface shall comply with the provisions of GB10095 and GB11365.

- 4. Seal packing or sealant is allowed when assembling the hydraulic system, but should be prevented from entering the system.

- 5. Parts and components (including purchased parts and external parts) that enter the assembly must have a certificate from the inspection department for assembly.

- 6. Parts must be cleaned and cleaned prior to assembly without burrs, flash, scale, rust, chips, oil, colorants and dust.

- 7. Before assembly, check the main fit dimensions of the parts and components, especially the interference fit size and related accuracy.

- 8. Parts are not allowed to rub, touch, scratch and rust during assembly.

- 9. When tightening screws, bolts and nuts, it is strictly forbidden to strike or use improper screwdrivers and wrenches. The screw groove, nut and screw, and the head of the bolt must not be damaged after tightening.

- 10. Fasteners that specify the tightening torque requirements must be torque wrenched and tightened to the specified tightening torque.

- 11. When the same part is tightened with multiple screws (bolts), each screw (bolt) should be crossed, symmetrical, stepwise, and evenly tightened.

- 12. When the tapered pin is assembled, the hole should be inspected with color. The contact rate should not be less than 60% of the length of the fit and should be evenly distributed.

- 13. The flat key and the upper side of the keyway should be evenly contacted, and there should be no clearance on the mating surface.

- 14. The number of flank contacts in the spline assembly is not less than 2/3, and the contact rate shall not be less than 50% in the length and height direction of the key teeth.

- 15. After the sliding flat key (or spline) is assembled, the phase accessories move freely without any unevenness.

- 16. Remove excess adhesive from the adhesive after bonding.

- 17. The outer ring of the bearing and the semi-circular hole of the open bearing housing and bearing cap are not allowed to jam.

- 18. The outer ring of the bearing should be in good contact with the semi-circular hole of the open bearing seat and the bearing cap. When the color is inspected, the bearing housing should be 120° symmetrical to the center line and the bearing cover should be 90° symmetric to the center line. Even contact. When using a feeler gauge within the above range, a 0.03 mm feeler gauge shall not be inserted into 1/3 of the width of the outer ring.

- 19. After the outer ring of the bearing is assembled, it should be in even contact with the end face of the bearing end of the positioning end.

- 20. After the rolling bearing is installed, it should be flexible and stable by hand rotation.

- 21. The joint surface of the upper and lower bearing pads should be closely attached and inspected with a 0.05mm feeler gauge.

- 22. When fixing the bearing bush with the positioning pin, the hinge and the pin should be drilled while ensuring that the face and end face of the pad are in flush with the opening and closing faces of the relevant bearing hole. Do not loosen after the pin is inserted.

- 23. The bearing body of the spherical bearing should be in uniform contact with the bearing housing. Check with the coloring method, the contact should not be less than 70%.

- 24. When the surface of the alloy bearing lining is yellow, it is not allowed to use. The nuclear separation phenomenon is not allowed within the specified contact angle. The area outside the contact angle shall not be greater than 10% of the total area of the non-contact area.

- 25. The reference end face of the gear (worm gear) and the shoulder (or the end face of the positioning sleeve) should be fitted together and inspected with a 0.05 mm feeler gauge. The verticality requirement of the gear reference end face and the axis should be ensured.

- 26. The joint between the gearbox and the cover should be in good contact.

- 27. Strictly inspect and remove sharp corners, burrs and foreign objects remaining during part processing before assembly. Ensure that the seal is not scratched when it is installed.

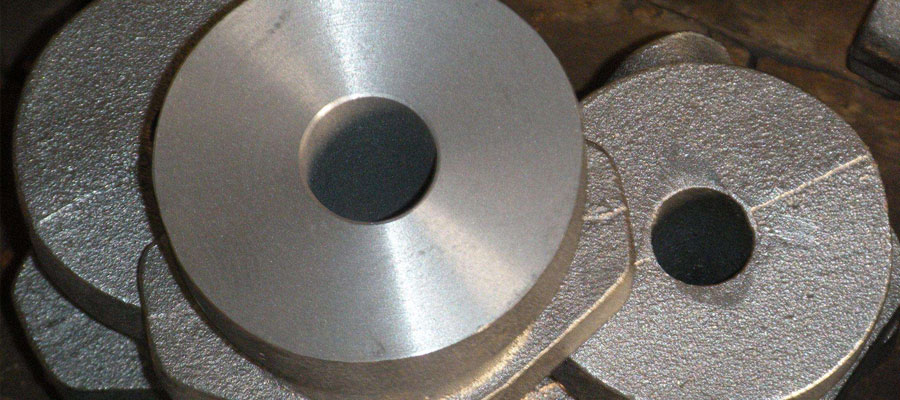

Casting requirements

- 1. Cold insulation, cracks, shrinkage and penetrating defects and severe defect defects (such as under-casting, mechanical damage, etc.) are not allowed on the surface of the casting.

- 2. The castings should be cleaned and free of burrs and burrs. Non-machining indicates that the pouring risers should be cleaned flush with the surface of the casting.

- 3. The casting and marking on the non-machined surface of the casting shall be legible and the position and typeface shall conform to the requirements of the drawing.

- 4. The roughness of the non-machined surface of the casting, sand casting R, not more than 50μm.

- 5. Castings should be removed from pouring risers, flying thorns, etc. The residual amount of the riser on the non-machined surface should be leveled and polished to meet the surface quality requirements.

- 6. The molding sand, core sand and core bone on the casting should be removed.

- 7. The casting has a slanted part, and its dimensional tolerance zone should be symmetrically arranged along the inclined surface.

- 8. The molding sand, core sand, core bone, fleshy, sticky sand on the casting should be smoothed and cleaned.

- 9. The wrong type, the boss casting, etc. should be corrected to achieve a smooth transition and ensure the appearance quality.

- 10. Wrinkles on the non-machined surface of the casting, the depth is less than 2mm, and the spacing should be greater than 100mm.

- 11. Non-machined surfaces of machine product castings require shot peening or drum treatment to achieve a cleanliness Sa2 1/2 level.

- 12. Castings must be water toughened.

- 13. The surface of the casting should be flat, and the gate, burr, sand, etc. should be removed.

- 14. Castings are not allowed to have casting defects such as cold partitions, cracks, holes, etc. that are detrimental to use.

Painting requirements

- 1. All surfaces of steel parts that need to be painted must be removed from rust, scale, grease, dust, dirt, salt and dirt before painting.

- 2. Before removing rust, remove the grease and dirt on the surface of the steel parts with organic solvents, lye, emulsifiers, steam, etc.

- 3. The time between the surface to be coated and the primer to be blasted or manually descaled shall not exceed 6h.

- 4. The surfaces of the rivet joints that are in contact with each other must be coated with a 30 to 40 μm anti-rust paint before joining. The lap joint is closed with paint, putty or adhesive. Repaint due to processing or welding damaged primer.

Piping requirements

- 1. All tubes before assembly should be removed from the tube ends, burrs and chamfered. Use compressed air or other methods to clear the debris and rust attached to the inner wall of the pipe.

- 2. Prior to assembly, all steel pipes (including pre-formed pipes) are degreased, pickled, neutralized, washed, and rust-proofed.

- 3. When assembling, tighten the pipe clamps, supports, flanges and joints that are screwed to prevent looseness.

- 4. The prefabricated pipe joints are subjected to a pressure test.

- 5. When piping is replaced or transported, the pipe separation port must be sealed with tape or plastic pipe to prevent any debris from entering and smashing the label.

Repair weldment requirements

- 1. The defects must be completely removed before welding, and the groove surface should be smooth and smooth, and no sharp corners should exist.

- 2. According to the defects of the steel castings, the defects in the welding area can be removed by shovel, grinding, carbon arc gouging, gas cutting or machining.

- 3. The sand, oil, water, rust and other dirt within 20mm around the weld zone and the groove must be thoroughly cleaned.

- 4. During the whole process of welding, the temperature of the preheating zone of the steel castings shall not be lower than 350 °C.

- 5. Apply welding as much as possible to the horizontal position, if possible.

- 6. During repair welding, the electrode should not be subjected to excessive lateral oscillation.

- 7. When the surface of the steel casting is welded, the overlap between the weld beads shall not be less than 1/3 of the width of the weld bead. The welding meat is full, the welding surface is free of burns, cracks and obvious nodules. The appearance of the weld is beautiful, and there are no defects such as biting meat, slag, pores, cracks and splashes; the welding wave is uniform.

Forging requirements

- 1. The nozzle and riser of the ingot should have sufficient removal amount to ensure that the forging has no shrinkage holes and severe deflection.

- 2. Forgings shall be forged on a forging press with sufficient capacity to ensure full forging inside the forgings.

- 3. Forgings are not allowed to have visible cracks, folds and other appearance defects that affect the use. Partial defects can be removed, but the depth of cleaning should not exceed 75% of the machining allowance. The defects on the non-machined surface of the forging should be cleaned and smoothed.

- 4. Forgings are not allowed to have white spots, internal cracks and residual shrinkage cavities.

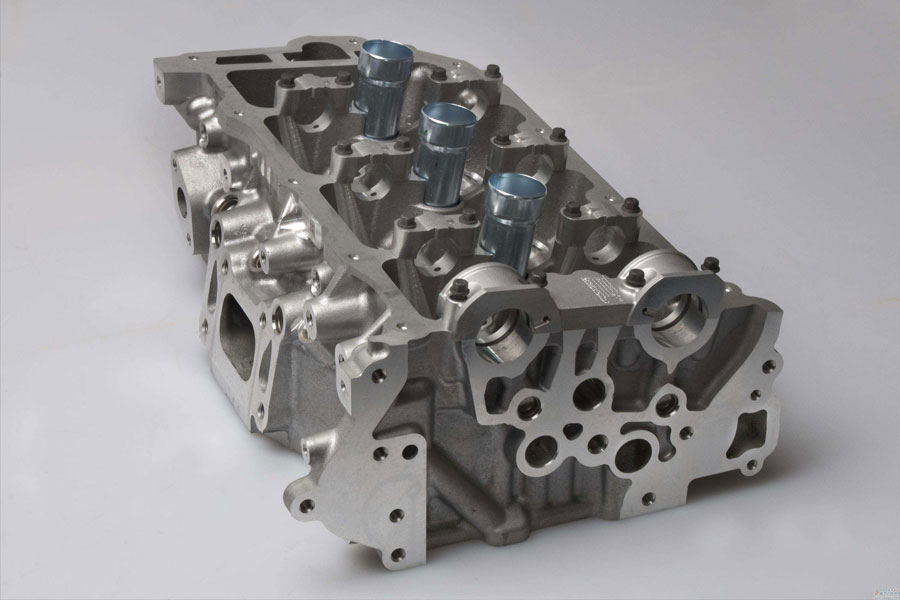

Cutting parts requirements

- 1. Parts should be inspected and accepted according to the process. After passing the previous process inspection, they can be transferred to the next process.

- 2. No burrs are allowed on the machined parts.

- 3. The finished parts should not be placed directly on the ground when they are placed. The necessary support and protection measures should be taken. The machined surface is not allowed to have rust and defects such as bumps and scratches that affect performance, life or appearance.

- 4. Roll the finished surface without peeling after rolling.

- 5. The parts after heat treatment in the final process shall have no scale on the surface. The finished mating surface and tooth surface should not be annealed

- 6. The surface of the machined thread is not allowed to have defects such as black skin, bumps, clasps and burrs.

Link to this article: Technical requirements for mechanical drawings

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:Technical requirements for mechanical drawings

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^