Difficulties and challenges in the light weight of Chinese cars

| The rapid development of the automotive industry has provided new opportunities for China’s manufacturing industry and brought more challenges. After decades of development, although China’s automobile industry has made great achievements, it still faces many difficulties in the field of lightweight research, mainly in the following aspects. |

First of all, China’s auto industry does not have a complete technical product standard for automotive lightweight components. Most automakers have been using traditional design concepts in body development projects. Second, China’s lightweight materials research started late. The application of materials in the body is not deep enough, and the types and performances of lightweight materials are still far from the foreign countries. Finally, due to the immature technology, the development, manufacturing and processing of new materials are costly, and it is difficult to form a perfect industrial chain in the short term. As a result, the cost of body application has increased significantly.

First of all, China’s auto industry does not have a complete technical product standard for automotive lightweight components. Most automakers have been using traditional design concepts in body development projects. Second, China’s lightweight materials research started late. The application of materials in the body is not deep enough, and the types and performances of lightweight materials are still far from the foreign countries. Finally, due to the immature technology, the development, manufacturing and processing of new materials are costly, and it is difficult to form a perfect industrial chain in the short term. As a result, the cost of body application has increased significantly.

At present, the world has introduced regulations on safety, emissions, fuel consumption and other aspects to enforce the safety and environmental performance of automotive products. With the continuous development and consumption of energy, China’s energy-saving and emission-reduction requirements for automobiles have become increasingly strict and safe. Energy conservation and environmental protection have clearly become the most important performance indicators for researchers in the automotive field. How to develop more environmentally friendly and energy-saving vehicles has become one of the most important directions in today’s automotive research field.

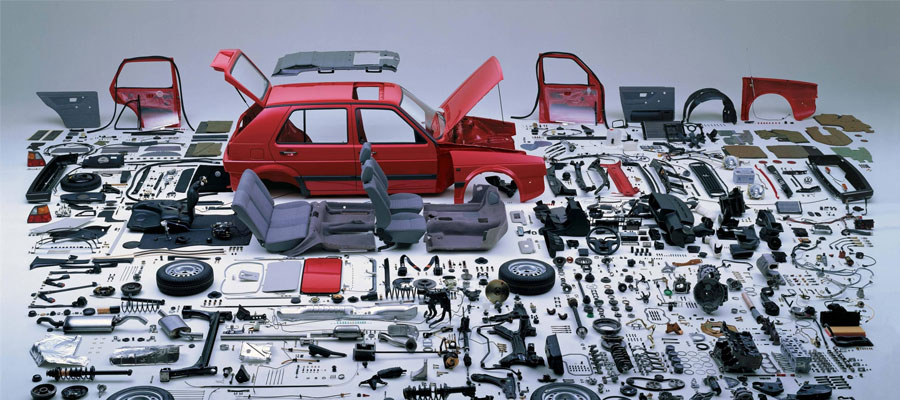

The fuel economy and emissions of automobiles are closely related to the quality of the vehicle. The research data shows that the lighter the quality of the car, the corresponding engine load can be reduced accordingly. When the vehicle weight is reduced by 10%, the fuel consumption is Can be reduced by 6% to 8%. Since the ordinary body-in-white body accounts for 20% to 35% of the total vehicle mass, the weight reduction of the vehicle body is essential for the weight reduction of the entire vehicle.

Due to the limited space for traditional steel process optimization and the difficulty in adapting processing equipment to new body materials, the use of new materials and processes is the main way to achieve lightweight body. The new lightweight materials can be mainly divided into low-density and high-strength materials. The current low-density lightweight materials are widely used in aluminum alloys, magnesium alloys, plastics and composite materials, while high-strength materials mainly refer to high-strength steels.

Application of new materials in lightweight

- ▶ High-strength steel with a yield strength of 210-550 MPa, characterized by low price, high structural strength, excellent fatigue resistance, and easy stamping and welding. It can fully utilize traditional production lines and is the material of choice for lightweighting at this stage. At present, high-strength steel materials are mainly used on the reinforcement parts of the body, such as the side pillars of the AB column, the floor side beam, the door anti-collision bar and other special important parts. The main mechanism of weight reduction is to make full use of its own ultra-high strength to reduce the thickness of the steel plate, and to achieve the weight reduction of the vehicle body, and also improve the safety performance of the vehicle. The application of high-strength steel materials in European and American countries has reached more than 55%, and the application of China’s own brands has also accounted for about 45%.

- ▶ Compared with steel, the density of aluminum alloy is only 35% of that of steel. The density of aluminum alloy is low, the impact resistance is good, and the energy absorption is twice that of steel. Therefore, it has great advantages in terms of safety collision performance. In addition, aluminum alloy has large reserves and high recycling rate. As a new lightweight material, it has been widely used in the field of automobile manufacturing. According to the research data, the aluminum product can achieve a weight reduction rate of about 50% in the body. Under the condition of satisfying the performance of the vehicle body, the weight of the vehicle body can be greatly reduced, and the weight of the vehicle body can be realized.

At present, the most widely used aluminum alloy materials are 5 series and 6 series. The 5 series is mainly used for body reinforcements, and the 6 series is mainly used for the frame and outer cover of the body. Audi A8, Jaguar XJ and other models have achieved all-aluminum body, the body is made of aluminum, the frame is three-dimensional structure, the outer cover is aluminum plate stamping, compared with similar steel body, the body quality is reduced by 30%-50% The fuel consumption is reduced by 5%-8%. - ▶ As the least dense of all metal materials, magnesium alloy has higher specific strength and specific stiffness than aluminum alloy and steel. In addition, it has good energy absorption, heat dissipation and noise reduction characteristics. One of the materials used at present is the casting gearbox housing, steering wheel, engine bracket, etc., which has great prospects for lightweight application. However, due to the small melting point of magnesium and the large solidification crystallization range, it is difficult to form a molten pool, the joint reliability is not high, and the chemical activity is high, and the danger in manufacturing and production is large, which greatly restricts the development of magnesium alloy lightweight materials. At this stage, the application range is lower than that of aluminum alloy materials.

- ▶ In the current application of body materials, in order to meet the requirements of lightweight, anti-corrosion, aesthetics, etc., non-metallic materials are increasingly favored by automotive developers. Lightweight non-metallic materials used in the body are mainly engineering plastics and composite materials. class.

Engineering plastic materials mainly include PE, PVC, PA, etc. Due to the low density, anti-corrosion, anti-vibration effect and excellent molding, these materials are produced by gas-assisted molding (GAM), water-assisted molding (WAM), and two-component injection molding. The processing technology of molding technology such as (DAM) has made it a great application in body materials, such as bumpers, fenders, and auto parts such as interior and exterior parts. Composite material refers to a combination of two or more materials, usually composed of a matrix and a reinforcement. The reinforcing material mainly includes fiber and polymer materials. Due to the low density, high strength and good high temperature and corrosion resistance of composite materials, it is mainly used in automotive components such as suspensions and frames.

Application of new technology in lightweight

- ▶ Laser tailor welding (TWB) is a processing method in which the slabs with different thickness, material, stamping performance, strength and surface treatment are first welded together, and then the overall stamping is performed [6]. In 1985, Volkswagen was the first to use laser tailor welding technology. Then, in 1993, North America also popularized this technology. China introduced laser tailor welding technology in the late 1990s. At present, Baosteel is the largest laser welding company in China and the largest laser welding company in Asia. It has more than 20 laser welding lines and can produce more than 20 million slabs per year. The market share is over 70%. Laser tailor welding technology has been widely used for body parts such as door inner panels, body side frames, floors and wheel covers.

- ▶ For high-strength steel sheets, as the yield strength and tensile strength of the material increase, the rebound of the sheet will become severe, the forming properties will be significantly reduced, and the dimensional accuracy of the parts will be difficult to ensure, especially for the strength exceeding For parts with 1000MPa and complex shapes, the general stamping process is difficult to form. At this time, the hot stamping technology of high-strength steel can be used well. The hot stamping forming technology mainly realizes the processing of sheet metal by the combination of heat treatment and high temperature forming. The process mainly includes sheet blanking, heating to austenite state, stamping forming, cooling quenching, and finally obtaining high-strength molding of uniform martensite structure. Components. Due to its high strength, non-rebound and light weight, the molded material has a wide range of applications, most of which are side-mounted AB columns, front and rear bumpers and other reinforcements.

- ▶ In addition to the above-mentioned forming technology, hydraulic forming processes, unequal thickness rolling processes, composite injection molding processes, etc. are widely used. These advanced molding processes meet the requirements of new lightweight materials and structures. It has opened up a broad way for the realization of lightweight roads.

Link to this article: Check out the new car materials and processes born in the challenge of car lightweighting

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:Check out the new car materials and processes born in the challenge of car lightweighting

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Alloy Wiki,thanks!^^